How to solve the problem of air leakage in fully automatic glue dispensers

Release time:2024-04-25Publisher:Jeenoce

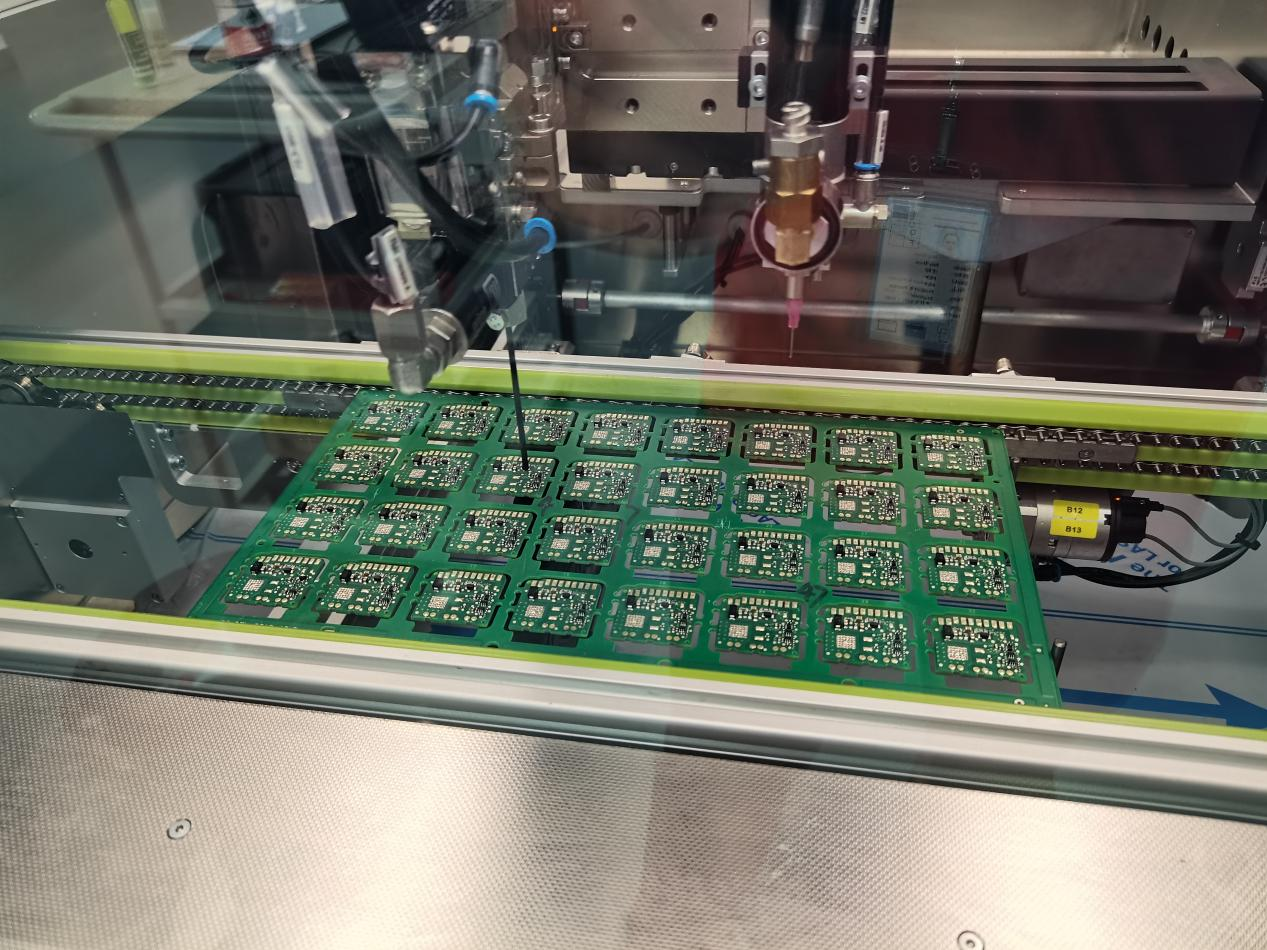

The fully automatic glue filling machine equipment is a professional equipment for manipulating liquids. The replacement of manual operation by automation technology equipment is the trend of the company's production and manufacturing reform and innovation. The high or low level of automation technology has to some extent harmed the company's development trend rate and management level. The key liquid for the fully automatic glue dispenser equipment is glue, which can be divided into many types. Some people place orders for two-component glue and two-component glue, and there will be significant differences in the specific dispensing process used in the dispensing process. For equipment with a small amount of glue control requirements, it is generally referred to as a fully automatic dispensing machine. Two component glue is usually used for filling, gluing, etc., with a relatively large clamping force to complete the preparation and mixing of glue. Therefore, this type of equipment is called a two component glue filling machine.

The key control glue driving force of the fully automatic glue filling machine equipment can be divided into pneumatic and electric types. Pneumatic type is achieved by compressing air and adjusting the size of the standard air pressure to meet the dispensing requirements; There are also electric types, which are dominated by instant glue. Here is a detailed introduction to equipment that uses pneumatic as the key driving force. If the dispensing machine experiences air leakage during the entire application process, it will immediately endanger the quality of dispensing. If there is a leakage situation, first analyze what caused the leakage, and then carry out treatment according to the specific situation.

If there is a leakage in the pressure tank of the fully automatic glue filling machine, it can be identified based on the location of the leakage. The leakage in the pressure tank is due to the lack of tightening of the clamping screws, or it may be due to damage to the sealing points of the pressure tank sealing cover and the barrel body. The actual solution is to replace the sealing gasket and tighten the screws. If there is a leak in the gas pipeline, it can be replaced immediately. It is necessary to check if there is any damage or serious folding. If the standard air pressure is too high, it is very likely to explode at the folding point. If there is air leakage in the transition head between the bronchi, then the transition head should be disassembled and replaced. If there is a common malfunction with the relay inside the control board, it should be disassembled and replaced. The actual glue dispensing machine leakage can be inspected from many areas above.