Types of spray valves and their application in the dispensing industry

Release time:2024-04-22Publisher:Jeenoce

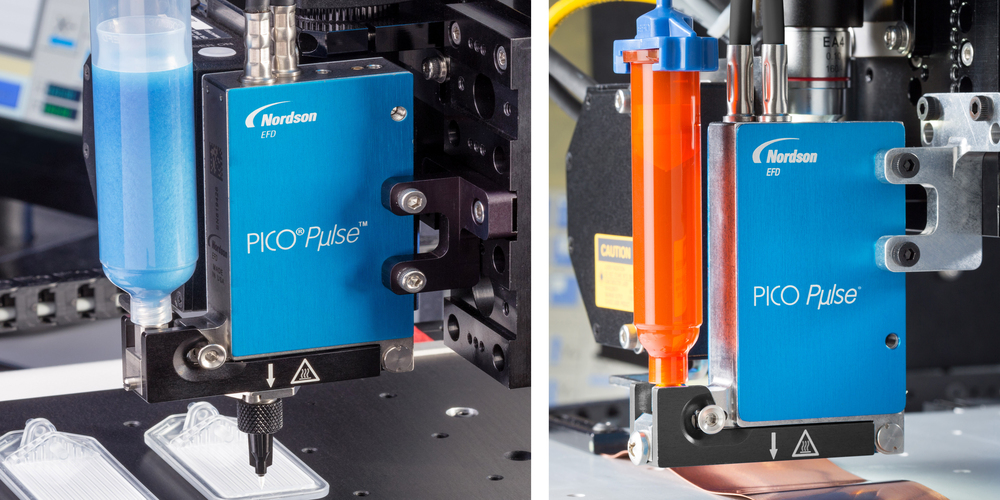

As a new and emerging accessory for dispensing machines, the spray valve is a novel thing for many friends who are not familiar with it. Due to the fact that the actual dispensing effect that the spray valve can achieve is something that traditional dispensing valves cannot achieve. Spray valve is based on pneumatic principle, using non-contact spray dispensing to prevent damage to fine components without touching the product; The injection valve accelerates the dispensing rate with less time to move to the Z-axis. The basic liquid dispensing frequency can reach 280Hz/mm, and the minimum usage can be as small as 2nl, achieving the actual effect of fine dispensing and high-speed dispensing.

Spray valves are generally divided into basic spray valves and solder paste spray valves. There are also thermosol spray valves, which are suitable for different liquids and dispensing processes. With precision machining equipment, they can be widely used for dispensing products in various industries, completing high-precision dispensing and bringing high efficiency to the company.

Below, we will introduce what types of spray valves are available and the scope of the strong adhesive industry they point to.

1. There are several key types of injection valves, including the needle type pneumatic non-contact high-speed injection type, commonly known as injection valves;

2. The super glue pointed by the jet valve includes UV glue thermosol epoxy resin glue silicone rubber paint printing ink silver gum rosin AB glue lubricating grease red glue ethanol building paint low viscosity glue medium viscosity high viscosity glue PU glue foam glue, etc;

3. The dispensing industry includes: mobile phone production, wire harness processing, laptop production, assembly, LED packaging, electronic equipment production and manufacturing, dispensing machinery and equipment production, etc.