The application of automatic dispensing machines in the automotive industry

Release time:2024-04-15Publisher:Jeenoce

With the sound development trend and the vigorous reflection of technological progress in automotive technology, the automotive manufacturing industry has achieved comprehensive development. The automobile assembly process is becoming more and more perfect, and the quality improvement is also getting better and better, with stronger reliability. In addition to the improvement of its own raw materials, the assembly process has achieved quality improvement. Many process flows have added the use of strong adhesive, thanks to the strong applicability of strong adhesive. Below, JEENOCE will tell you a few small stories about the application of dispensing technology.

1. Key component - engine

(1) Engine hydraulic seal

Sealing is a more critical part of engine assembly. Before the application of dispensing technology, manufacturers usually chose customized appearance design sealing rings. After the introduction of dispensing technology, traditional sealing rings were gradually replaced, and customized sealing rings were no longer available. Automated machinery can be completed according to the regulations of sealed colloidal solutions through simple programming. In order to achieve uniformity and reliability of dispensing, industrial control automated dispensing machinery and equipment have crucial functions.

(2) Engine lubricating grease

Lubricating grease is widely used in engines, and with the prevalence of automation control, industrial automation dispensing machines and equipment are gradually replacing manual dispensing of lubricating grease, ensuring a stable amount of vegetable grease and improving productivity.

(3) Engine thread sealant

To ensure reliability in long-term work, thread sealant has been introduced into engine assembly, and automated technology for gluing remains an indispensable part.

2. Electronic components - Automotive electronic components

(1) Reasonable improvement of comfort in automotive electronic components, from mechanical equipment dashboard to LCD screen dashboard, from mechanical equipment steering assistance to electronic device steering assistance, from manual elevators to electric elevators, and so on.

(2) Reasonable improvement coefficient of automotive electronic components, tire pressure monitoring device, front and rear left and right radar detection, reverse rearview, automatic cruise control, ECU alarm, etc

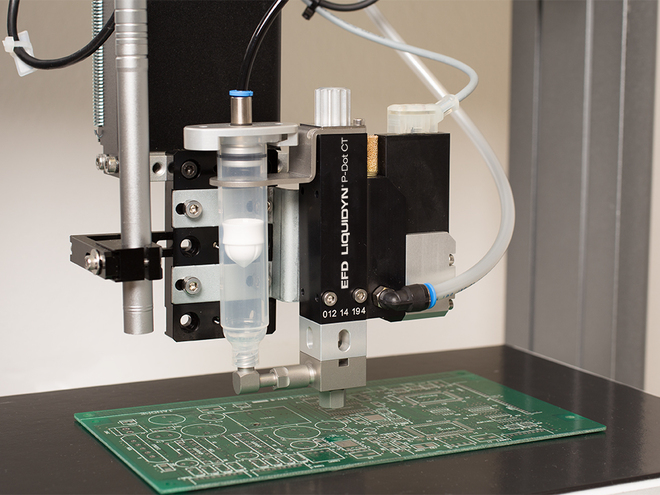

(3) The development trend of automotive electronic devices cannot be separated from the accurate manipulation of ECUs and each component. The important connection of ECUs is the PCB board, and the stability of PCBs usually needs to be achieved by putting effort into strong adhesive, such as coating process, gluing process, foot wrapping, red adhesive, and RTV fixation.

3. New Energy Technology Vehicles - Rechargeable Battery Modules

In recent years, with the improvement of gas natural environment regulations, new energy technology vehicles have been continuously developing, and the market share of electric vehicles has shown a steady growth trend. The technological advancement of battery drive has also been rapidly developing. The assembly of rechargeable battery modules cannot be separated from the adhesion of strong adhesive, the overheating of rechargeable battery modules cannot be separated from thermal conductive adhesive, the lithium battery protection plate of rechargeable battery modules cannot be separated from the application of coating technology.