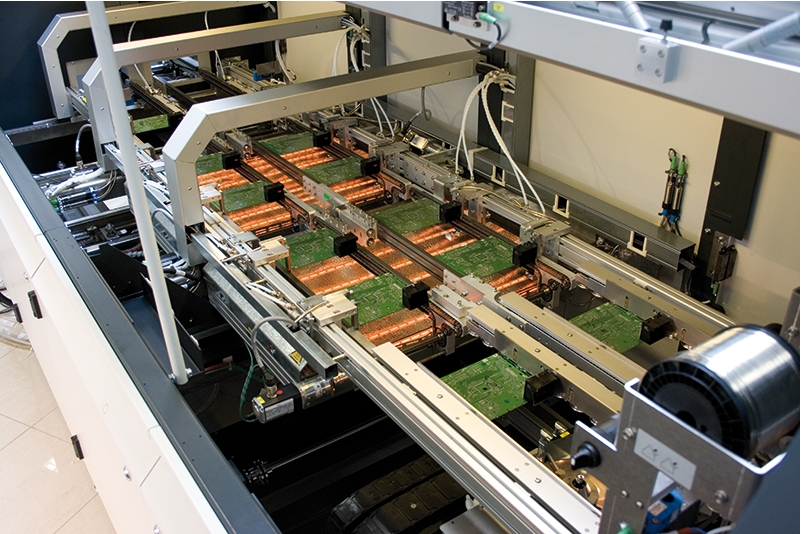

How to achieve better soldering results with lead-free reflow soldering

Release time:2024-03-21Publisher:Jeenoce

The temperature of lead-free reflow soldering is much higher than that of lead reflow soldering, and the temperature setting of lead-free reflow soldering is also difficult to adjust, especially because the process window of lead-free reflow soldering is very small, so the control of lateral temperature difference is very important. The large lateral temperature difference in reflow soldering can cause batch defects. So how can we reduce the lateral temperature difference in reflow soldering to achieve the ideal lead-free reflow soldering effect? JEENOCE starts with four factors that affect the effectiveness of reflow soldering.

1. Hot air transfer in lead-free reflow soldering furnace

At present, the mainstream lead-free reflow soldering adopts the heating method of full hot air, and infrared heating has also appeared in the development process of reflow soldering furnaces. However, due to the different infrared absorption reflectivity of devices with different colors and the shadow effect caused by adjacent original devices blocking, both of these situations will cause temperature differences and the risk of lead soldering jumping out of the process window. Therefore, infrared heating technology has gradually been phased out in the heating method of reflow soldering furnaces. In lead-free welding, it is necessary to pay attention to the heat transfer effect, especially for large heat capacity original devices. If sufficient heat transfer cannot be obtained, it will lead to a significantly slower heating rate than small heat capacity devices, resulting in a lateral temperature difference. Compared to using a fully hot air lead-free reflow soldering furnace, it will reduce the lateral temperature difference of lead-free reflow soldering.

2. Chain speed control for lead-free reflow soldering furnaces

Lead free reflow soldering chain speed control will affect the lateral temperature difference of the circuit board. Generally speaking, reducing the chain speed will give devices with high thermal capacity more heating time, thereby reducing the lateral temperature difference. However, after all, the setting of the furnace temperature curve depends on the requirements of the solder paste, so it is not practical to limit the chain speed in actual production. This depends on the use of the solder paste. If there are many large components on the circuit board that absorb heat, it is recommended to lower the reflow soldering transportation chain speed so that large SMT components can fully absorb heat.

3. Control of wind speed and air volume for lead-free reflow soldering furnace

If the other conditions in the lead-free reflow soldering furnace are kept unchanged, and only the fan speed in the lead-free reflow soldering furnace is reduced by 30%, the temperature on the circuit board will decrease by about 10 degrees. It can be seen that the control of wind speed and air volume is important for furnace temperature control. In order to achieve control of wind speed and air volume, it is necessary to pay attention to two points: good control can reduce the lateral temperature difference in the lead-free reflow soldering furnace and improve the welding effect:

⑴ The speed of the fan should be controlled by variable frequency to reduce the impact of voltage fluctuations on it;

⑵ Try to reduce the exhaust air volume of the equipment as much as possible, as the central load of the exhaust air is often unstable and can easily affect the flow of hot air in the furnace.

4. Lead free reflow soldering has good stability and can reduce the temperature difference inside the furnace

Even if we obtain the optimal lead-free reflow furnace temperature curve setting, achieving it still requires stability, repeatability, and consistency of lead-free reflow soldering to be guaranteed. Especially in lead production, if there is slight drift due to equipment reasons, it is easy to jump out of the process window and cause cold soldering or damage to the original components. So, more and more manufacturers are beginning to demand stability testing for their equipment.