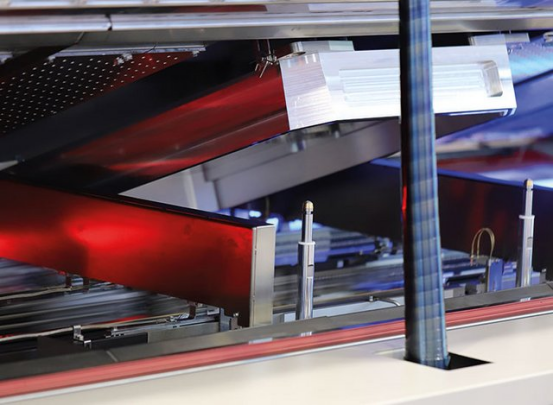

Real time monitoring system for reflow soldering

Release time:2024-03-08Publisher:Jeenoce

Automatic reflow soldering is equipped with a real-time monitoring system for reflow soldering to monitor the temperature inside the reflow soldering furnace. It is like a camera that can monitor and record the reflow soldering furnace 24 hours a day, track each product in the process, and record the temperature inside the furnace. It can ensure the maintenance of excellent process capability, identify existing problems before potential defects occur, and provide detailed and objective data to process personnel at any time, eliminating the problem of fuzzy verification of furnace temperature curves.

For the same product, only one temperature curve needs to be measured as the reference curve. The monitoring system will monitor the temperature changes at different positions in the furnace cavity in real time through thermocouples in the temperature detection tubes on both sides of the track, thereby inferring the real-time temperature of each test point on the PCB. Using the reference curve as the standard, an accurate simulation curve will be inferred for each PCB board in the process. And it is necessary to measure the temperature curve several times a day, just like traditional methods.

The simulated temperature curve can be retained. When there is doubt about the SMT welding quality at a certain moment, the simulated temperature curve in the furnace can be retrieved by inputting the processing time on the reflow soldering computer, and this can be used to check whether the furnace temperature is abnormal.