Heating method of hot air reflow soldering

Release time:2024-03-07Publisher:Jeenoce

The heating method of hot air reflow soldering is to divide the hot air reflow soldering furnace into several independent temperature controlled zones, each of which is further divided into two temperature zones: upper and lower. The schematic diagram of the structure of each temperature zone is shown in the following figure. There is a heating tube installed in the temperature zone, and the hot air motor drives the wind wheel to rotate. The formed hot air is blown out through a special structure of air duct through a rectifier plate, making the hot air evenly distributed in the temperature zone.

The heating system of hot air reflow soldering mainly consists of hot air motor, heating tube, thermocouple, solid-state relay SSR, temperature control module, and other parts. The hot air reflow soldering furnace has the characteristics of uniform heating and stable temperature. The total reflow soldering furnace transfers heat energy through the laminar movement of hot air, and uses a heater and fan to continuously heat up and circulate the air inside the furnace. The welded parts are heated by the hot gas in the furnace, thus achieving welding.

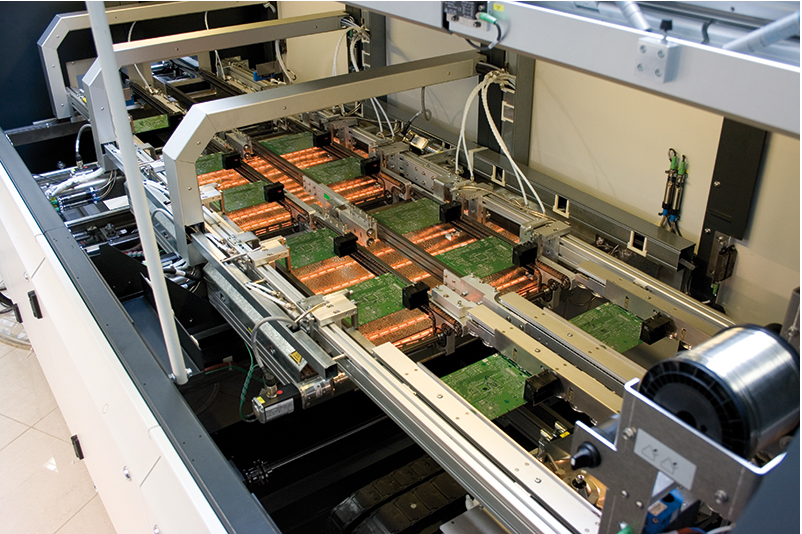

The overall structure of the hot air reflow soldering furnace is mainly divided into five main parts: heating zone, cooling zone, furnace gas circulation device, exhaust gas emission device, and PCB conveying. The hot air reflow soldering furnace is divided into two sealed boxes, upper and lower, with a conveyor belt in the middle. The length of some furnace bodies mainly varies depending on the number of heating and cooling zones. Hot air reflow soldering is heated by the upper and lower heating systems in each temperature zone of the reflow soldering furnace.