Analysis of the working principle of piezoelectric dispensing valve

Release time:2024-03-07Publisher:Jeenoce

Piezoelectric dispensing valve is a precision dispensing equipment commonly used in industrial production. Its working principle is to control and regulate the flow of glue through the piezoelectric effect. This article will provide a detailed introduction to the working principle of the dispensing valve, including the implementation mechanism, control method, characteristics, and application fields of the piezoelectric effect.

The implementation mechanism of piezoelectric effect refers to the phenomenon of polarization in certain substances when subjected to mechanical stress, and mechanical deformation can also occur when an external electric field is applied. Piezoelectric materials are widely used in various fields such as sensors, actuators, and actuators due to their special electromechanical coupling effect. The piezoelectric dispensing valve utilizes this characteristic to achieve precise glue control.

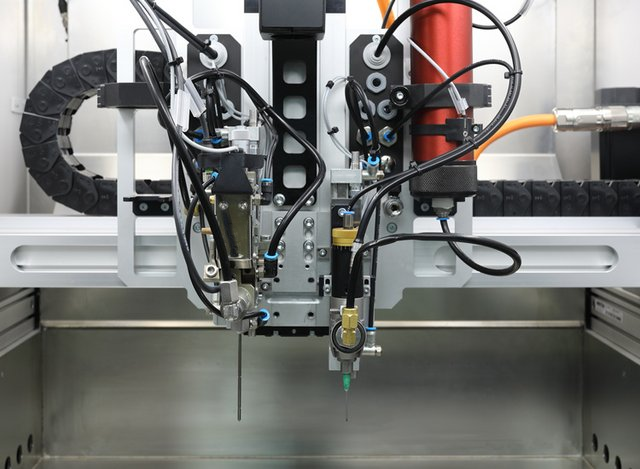

The control method of a piezoelectric dispensing valve usually consists of a control instrument, piezoelectric ceramic sheets, and a nozzle. The control instrument is responsible for controlling the flow and stop of glue, and controlling parameters such as spraying time, speed, and spacing by operating buttons on the instrument or through external signals. Piezoelectric ceramic sheets serve as sensors and actuators, and their size is changed by applying voltage to control the flow of adhesive. The nozzle is responsible for evenly spraying the glue onto the area that needs to be glued.

Working principle: When the control instrument sends a signal to the piezoelectric dispensing valve, the piezoelectric ceramic plate on the nozzle will receive a voltage signal and respond to it. The voltage signal causes deformation of the piezoelectric ceramic sheet, thereby changing the channel size of the nozzle. When the size of the channel decreases, the pressure increases and the glue is pushed out. On the contrary, as the size of the channel increases, the pressure decreases and the glue stops flowing. By controlling the voltage and time, precise glue dispensing can be achieved.

The piezoelectric dispensing valve has the following characteristics and application areas: high precision: precise dispensing can be achieved by controlling voltage and time- High speed: can control the flow rate of glue to meet different processing needs- Adjustable: By adjusting the channel size and voltage, the glue flow rate can be precisely adjusted- Strong stability: Piezoelectric ceramic sheets have stable performance, ensuring the stability of dispensing quality.

Piezoelectric dispensing valves have a wide range of applications in fields such as electronics, electrical appliances, and medical devices. For example, areas such as electronic component soldering, printed circuit board packaging, mobile phone screen bonding, and medical device assembly all require the use of dispensing valves for precise glue control. Its high precision, high speed, and adjustable characteristics make piezoelectric dispensing valves an indispensable key equipment in these industries.

The precise control of glue is achieved through the piezoelectric effect, and piezoelectric dispensing valves play an important role in industrial production. Its working principle is simple and efficient, making the dispensing process more convenient, fast, and accurate. With the continuous progress of technology, piezoelectric dispensing valves will show broader application prospects in more fields.