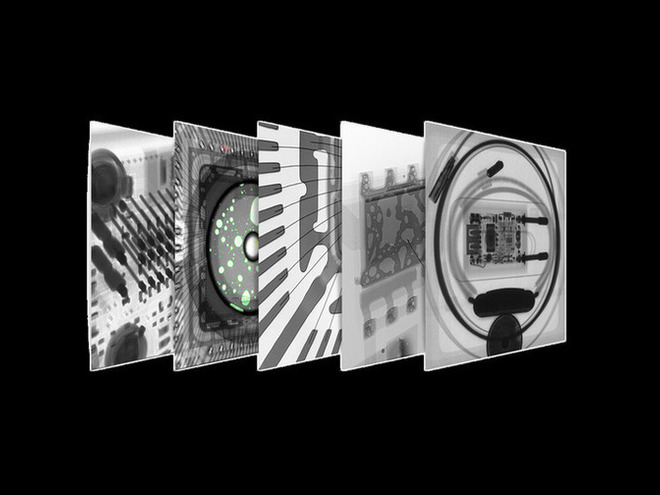

How to perform detection operations on BGA IC chips using X-RAY?

Release time:2024-02-28Publisher:Jeenoce

BGA, IC chips, IGBT semiconductors and other electronic components are indispensable cores of electronic products, which affect the performance stability of electronic product use and play a crucial role in product market circulation and word-of-mouth promotion.

The current market uses X-RAY or ultrasound as the main non-destructive testing method for detecting the internal structure of BGA, IC and other samples. The difference between X-RAY equipment and ultrasound testing is that after X-RAY testing the sample, the image image can be saved for later technicians to recheck the product, while ultrasound cannot be stored.

At present, X-RAY testing equipment is divided into multiple professional uses, such as medical testing and industrial testing, while JEENOCE's X-RAY is mainly used for industrial electronics, and can perform testing operations on different packaging products such as semiconductors, resistors, capacitors, BGA, IC chips, lithium batteries, etc.

X-RAY has the following characteristics:

1. X-RAY has a high geometric magnification of up to 800X, allowing for clearer viewing of micro details;

2. Strong detectability, relevant testing can be carried out for products of different sizes and weights, and specific limit values can be consulted with customer service;

3.360 degree dead angle detection to ensure the presentation of product details;

4. Detection scope: uneven dispensing, broken wires, ground wires, internal bubbles, abnormal welding, etc;