What are the basic factors to consider when using industrial CT?

Release time:2024-02-23Publisher:Jeenoce

Industrial CT was developed by J. in 1917 Random proposed, but it was not until the mid to late 1970s that it began to be widely applied in non-destructive testing. In recent years, with the progress of computer science and the development of detector technology, the performance of industrial CT has been improving year by year. Industrial CT non-destructive testing has been widely used as a practical non-destructive testing method in various fields such as aerospace and nuclear energy due to its wide adaptability to materials, ability to detect complex parts, ability to determine defect locations and sizes, and high detection accuracy.

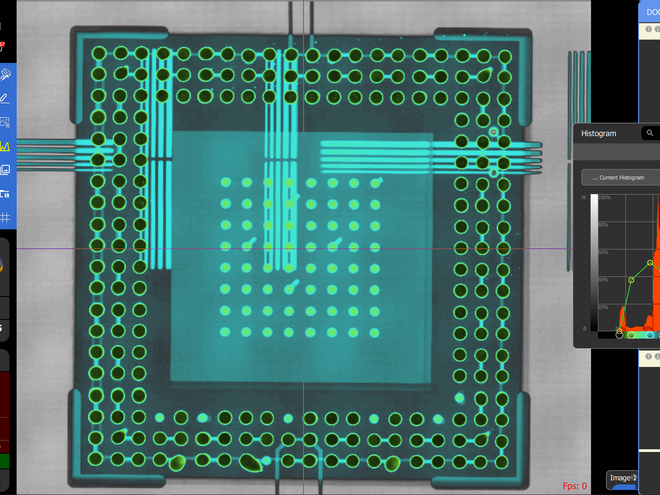

Industrial CT can clearly, accurately, and intuitively display the internal structure, composition, material, and defect status of the tested object in the form of two-dimensional sectional images or three-dimensional stereoscopic images without damage to the tested object. It is known as today's non-destructive testing and assessment technology. Industrial CT technology involves multiple disciplines such as nuclear physics, microelectronics, optoelectronics, instrumentation, precision machinery and control, computer image processing and pattern recognition, and is a technology intensive high-tech product.

Compared with traditional measurement techniques, CT has many advantages, including the ability to measure complex and/or difficult to access sample features in a non-contact and non-destructive manner through high-density information.

In product testing, this is fundamental because part costs are usually high and destructive testing is not allowed. Industrial CT also enables engineers to quickly evaluate the qualification of parts before performing expensive processing.

The basic factors to consider when using industrial CT include the achievable geometric magnification, which depends on the size and geometric shape of the part, the material and wall thickness of the part.

Performance indicators of industrial CT equipment:

1. Detection scope: mainly describes the detection objects of ICT. If the maximum wall thickness of the steel can be transmitted, the * large turning diameter of the steel part, the * large height or length of the steel part, and the maximum weight of the steel part can be detected.

2. X-ray source used: X-ray energy, working voltage, working current, and focal length.

3. ICT scanning methods: What scanning methods can be used, and whether they have digital radiographic detection or real-time imaging capabilities.

4. Scanning detection time: refers to the collection time of scanning to obtain fault data. This also includes image reconstruction time.