Industrial CT: A New Leader in Exploring the Internality of Matter

Release time:2024-02-18Publisher:Jeenoce

With the development of technology, more and more technologies are being applied in the production field. Among them, industrial CT, as a non-destructive detection technology, has received increasing attention due to its ability to perform three-dimensional imaging of the interior of objects.

1、 The principles and advantages of industrial CT

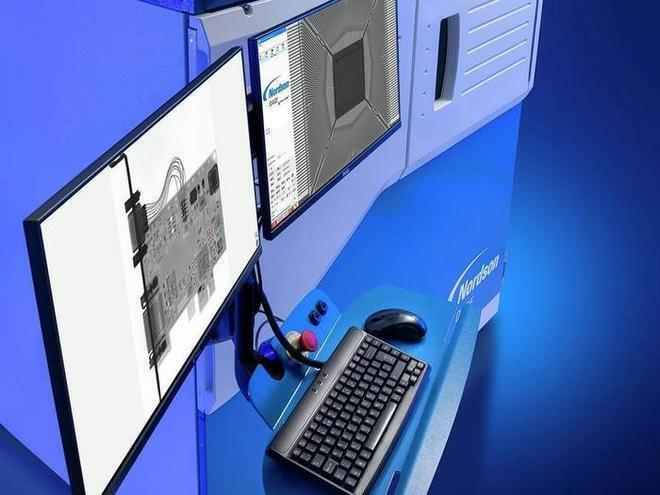

The device uses X-rays or other radiation sources to irradiate the object to be tested, transfer the radiation to the detector, and convert the data into a three-dimensional image through a computer. This imaging method is similar to medical CT, but in this device, the detected object is usually much larger than medical CT and requires higher resolution and more accurate imaging.

Compared to traditional non-destructive testing techniques, this device has the following advantages:

1. Non intrusive: The device does not need to come into contact with the object being tested and will not cause any damage to it.

2. High precision: This device can perform three-dimensional imaging of objects and accurately measure important parameters such as size, shape, and position inside the object.

3. Comprehensiveness: This device can detect any defects or structures inside objects, whether it is cracks, holes, or material deformation, which can be detected.

4. Efficiency: The device can perform multiple detection tasks simultaneously and complete a large amount of data processing and analysis work in a short period of time.

2、 The application of industrial CT in the production field

1. Quality control: This equipment can perform non-destructive testing on components, finished products, or raw materials during the manufacturing process to ensure that their quality meets the requirements. For example, in automobile manufacturing, this device can detect defects or material deformations in components such as wheels, engine parts, brakes, and transmission systems.

2. Research and development: This device can assist enterprises in developing and improving new products. For example, in the aerospace field, this device can perform three-dimensional imaging of aircraft components to evaluate their performance and lifespan parameters. In the electronics industry, this device can detect the internal structure of integrated circuits and packaging components to ensure their quality and reliability.

3. Healthcare: This device can also be applied in the healthcare field. For example, in the field of dentistry, this device can perform three-dimensional imaging of teeth to assist in diagnosis and treatment. In the manufacturing of medical devices, this device can detect defects in medical equipment to ensure its quality and safety.

3、 The development trend of future industrial CT

With the continuous advancement of technology, this device will also develop into more advanced and multifunctional devices. For example, the future device may have the following characteristics:

1. Higher resolution and accuracy: With the advancement of technology, the resolution and accuracy of this device will be further improved, allowing for more accurate detection of details and structures inside objects.

2. Wider application scope: With the continuous improvement of the equipment technology, its application scope will also be further expanded, including biomedical, cultural heritage protection and other fields.

3. More intelligent and automated: In the future, this device will be more intelligent and automated, capable of automatically controlling imaging processes and data processing, improving work efficiency and accuracy.

In summary, industrial CT, as a non-destructive testing technology, has broad application prospects in the production field. With the continuous advancement of technology, it will become a new tool for exploring the internal workings of matter, providing strong support for quality control, research and innovation in the production field.