What are the main advantages and disadvantages of X-ray CT?

Release time:2024-01-29Publisher:Jeenoce

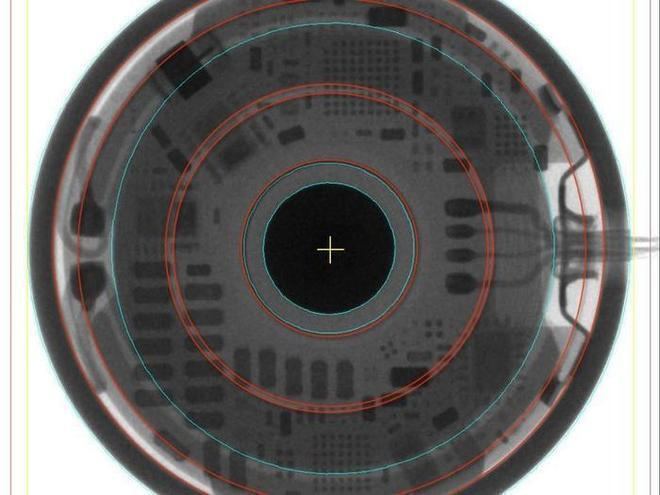

The X-ray CT scheme can intuitively display the size and shape of internal defects in the workpiece, making it easy to determine the nature of defects. The X-ray film can be used as the original record of inspection for multiple parties to study and long-term preservation, and has high sensitivity for non-destructive testing of thin-walled workpieces. Sensitive to volumetric defects, the planar distribution of defect images is true and the size measurement is accurate. There is no strict requirement for the surface smoothness of the workpiece, and the grain size of the material has little effect on the detection results. It can be applied to the detection of internal defects in various materials, so it is widely used in the welding quality inspection of pressure vessels.

However, the X-ray CT method consumes high equipment costs such as X-ray film, has a long film evaluation cycle, slow inspection speed, and low sensitivity to detecting thick walled workpieces. It is only suitable for detecting volumetric defects such as porosity, slag inclusion, shrinkage, and looseness. It can be qualitative but not quantitative, and is not suitable for structures with cavities. The inspection sensitivity of diagonal welding and T-joints is low, making it difficult to detect defects such as cracks with small gaps and lack of fusion, as well as internal delamination defects in forgings, pipes, rods, and other profiles.

The advantages and disadvantages of X-ray CT are mainly reflected in: the advantage is non-destructive testing, which can achieve detection results without the need to open the sample, and direct imaging, which can analyze and save data on imaging; The disadvantage is that X-ray is used to penetrate the sample and image the inside of the sample for detection. The length of the X-ray wave is strong, and if radiation leaks, it will have a certain impact on the physical health of the operator.

X-ray CT has various forms and uses, but its basic composition is very similar, with four main components.

1. A high stability X-ray source provides the required X-rays for measurement. Changing the anode target material of the tube can change the wavelength, and adjusting the anode voltage can control the intensity of the X-ray source.

2. The adjustment mechanism system for sample and sample position orientation. The sample must be a solid block of single crystal, powder, polycrystalline or microcrystalline.

3. X-ray detectors detect diffraction intensity or simultaneously detect diffraction direction, and polycrystalline diffraction pattern data can be obtained through instrument measurement and recording systems or computer processing systems.

4. The processing and analysis systems for diffraction patterns, as well as modern X-ray CT, come with computer systems equipped with diffraction pattern processing and analysis software, which are characterized by automation and intelligence.