What are the issues that affect the quality of PCB reflow soldering?

Release time:2024-01-24Publisher:Jeenoce

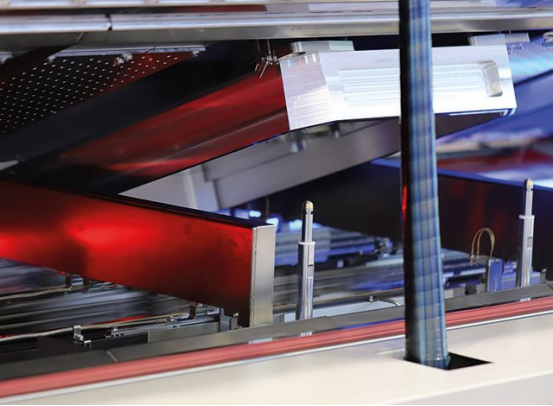

PCB reflow soldering is one of the key processes in SMT. The reflow soldering furnace process involves the PBC board printed with solder paste and mounted with components passing through the reflow soldering furnace to complete the fully automatic welding process of drying, preheating, melting, cooling and solidification. During this process, various defects such as bridging, standing monument, missing or insufficient soldering often occur. In addition, there are other factors that can affect the quality of PCB reflow soldering. Today, JEENOCE will share with you which factors can affect the quality of PCB reflow soldering.

1、 PCB pad design for circuit boards

The quality of reflow soldering is directly related to the design of PCB pads on circuit boards. If the PCB pad design meets international standards, a slight deviation during installation can be corrected by the surface tension of the molten solder when passing through the HELLER reflow soldering furnace (known as self positioning or self correction effect); On the contrary, if the PCB pad design does not comply with international standards, even if the mounting position is very accurate, soldering defects such as component displacement and suspension bridges may occur after reflow soldering.

2、 Quality of solder paste

Solid solder paste is an essential material for SMT reflow soldering process. It is a paste like soldering material formed by uniformly mixing alloy powder (particles) with a paste like flux carrier. Among them, alloy particles are the main component for forming solder joints, while flux is used to remove the oxide layer on the welding surface and improve wettability. Ensuring the quality of solder paste has a significant impact on welding quality.

3、 Component quality and performance

As an important component of SMT mounting, the quality and performance of components directly affect the pass through rate of reflow soldering. As one of the reflow soldering objects, it is necessary to have a basic requirement of high temperature resistance. Moreover, some components have a relatively large thermal capacity, which also has a significant impact on welding. For example, PLC, QFP, and a discrete chip component usually have a larger thermal capacity, making it more difficult to weld large area components than small ones.