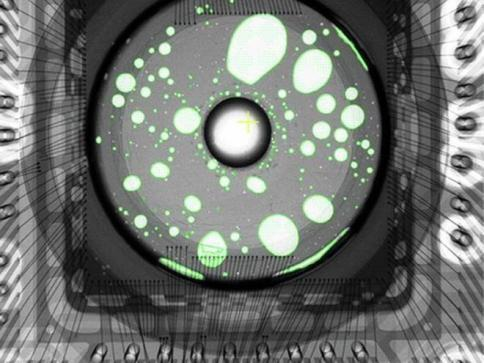

The DR detection system includes the following important components

Release time:2024-01-17Publisher:Jeenoce

The DR detection system consists of an electronic cassette, a scanning controller, a system controller, an image monitor, etc. It directly converts X-ray photons into digital images through the electronic cassette, and is a generalized direct digital X-ray photography. Narrowly defined, Direct Digital Radiography, also known as DDR (Direct Digital Radiography), typically refers to digital radiography using image conversion technology with flat panel detectors, and is a true direct digital X-ray imaging system.

The DR testing system is suitable for non-destructive testing in industries such as electronics, petroleum, chemical, refractory materials, steel pipes, die-casting, boilers, automobiles, pressure vessels, high-speed rail, aviation, aerospace, etc. Realize dynamic real-time imaging, with fast operation speed and high image quality, improving detection speed and reliability. The system is equipped with a mechanical transmission device, which can be selected from different angles to observe internal defects and measure dimensions of the workpiece with excellent dynamic effects. Especially suitable for online detection. Due to our outstanding contribution in this technology, our company was designated by the National Development and Reform Commission as a high-tech industrialization base for X-ray real-time imaging detection systems in 2004.The DR detection system includes the following important components:1. Digital flat panel detector2. Image processing workstation3. Professional level image acquisition and processing software4. Portable X-ray machine and trolley boxThe DR detection system has two communication methods, wireless and wired, which are convenient for on-site engineering applications. At the same time, the tablet is equipped with two lithium batteries, which can ensure continuous operation for more than 6 hours. The design principles of reasonable layout and portability integrate the main components of the imaging system into a trolley box, avoiding equipment damage during transportation and storage and reducing the workload of operators.