Comparison of advantages and disadvantages of medium temperature solder paste reflow soldering

Release time:2024-01-16Publisher:Jeenoce

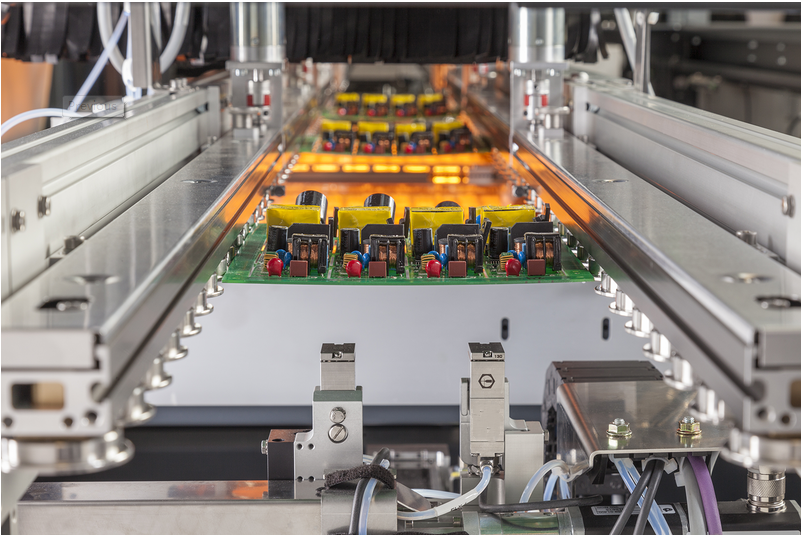

Medium temperature solder paste reflow soldering is a soldering method used for soldering electronic components. It can achieve soldering at low temperatures and effectively reduce pollution during the soldering process. JEENOCE would like to share the advantages and disadvantages of medium temperature solder paste reflow soldering.

The advantages of reflow soldering with medium temperature solder paste

1. Low soldering temperature: The soldering temperature for medium temperature solder paste reflow soldering is only 150-200 ℃, much lower than traditional soldering temperatures, which can effectively protect electronic components from damage.

2. Fast welding speed: The welding speed of medium temperature solder paste reflow soldering is much faster than traditional welding methods, which can greatly improve production efficiency.

3. High welding quality: Medium temperature solder paste reflow soldering can ensure welding quality and effectively prevent leakage and open circuit of welded joints.

4. Environmentally friendly: Medium temperature solder paste reflow soldering can effectively reduce pollution during the welding process and protect the environment.

Disadvantages of medium temperature solder paste reflow soldering

1. High cost: The cost of medium temperature solder paste reflow soldering is much higher than traditional soldering methods, so it is not suitable for large-scale production.

2. Complex operation: The operation requirements for medium temperature solder paste reflow soldering are higher than traditional welding methods, and the operator needs to have a high level of technical proficiency.

3. Unstable welding quality: Due to the lower welding temperature of medium temperature solder paste reflow soldering, the welding quality is not stable enough, which can easily lead to problems such as leakage and open circuit of the welding joint.

4. Low welding efficiency: The welding efficiency of medium temperature solder paste reflow welding is lower than that of traditional welding methods, so it is not suitable for large-scale production.

In summary, medium temperature solder paste reflow soldering has advantages such as low welding temperature, fast welding speed, high welding quality, and environmental friendliness. However, it has disadvantages such as high cost, complex operation, unstable welding quality, and low welding efficiency. Therefore, when using medium temperature solder paste reflow soldering, appropriate welding methods should be selected according to the actual situation to ensure welding quality.