AOI automatic optical instrument defect detection

Release time:2024-01-15Publisher:Jeenoce

The development of AOI technology towards intelligence is an inevitable requirement brought about by the development of SMT. Under the development characteristics of miniaturization, high-density, rapid assembly, and diversified varieties of SMT, the amount of detection information is large and complex. Whether in terms of real-time detection feedback or the correctness of analysis and diagnosis, relying on manual analysis and diagnosis of the quality information obtained from AOI is almost impossible. The intelligent AOI technology that replaces manual automatic analysis and diagnosis has become an inevitable development trend.

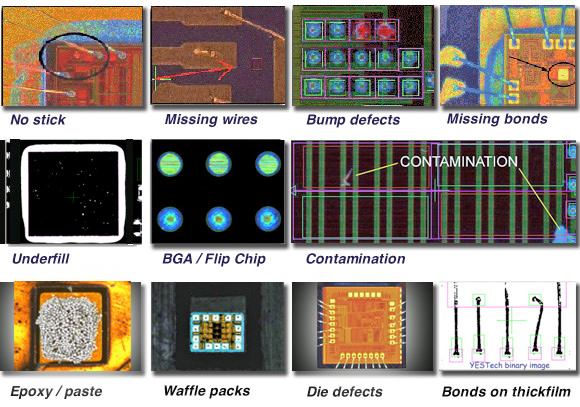

Research on feature extraction, defect recognition, and classification of various defects; In response to the problems of small defects, diverse types of defects, and difficult to determine features that need to be detected in high-density PCB visual inspection systems, research is conducted on feature extraction techniques and classification methods for various different defects. Machine learning methods are used to design different classifiers, and the classification performance and errors of different classifiers are compared and analyzed, The use of optimized classifiers can achieve rapid detection and accurate classification of defects, and maximize the intelligence level of classifiers.

AOI requires a close integration of defect statistics and classification with SPC during the detection process. The so-called SPC, also known as Statistical Process Control, mainly refers to the application of statistical analysis technology to monitor the production process in real time, scientifically distinguish between random and abnormal fluctuations in product quality during the production process, and provide early warnings for abnormal trends in the production process, so that production management personnel can take timely measures to eliminate anomalies, restore process stability, and achieve the goal of improving and controlling quality.

Generally, AOI can achieve two types of measurements, namely defect detection (traditional AOI applications) and differential measurement for each PCB. For effective process control, both types of measurements are required. Differential measurement is crucial for real-time SPC applications, as it varies depending on the type of AOI system and its location on the production line. In order for AOI/SPC to be successfully used on production lines, the AOI system must be able to generate error handling and alarms. The misjudgment rate and defect detection sensitivity will be affected by inspection parameters. The more production process variables there are, the greater the possibility of misjudgment and the greater the complexity of defect detection. Therefore, choosing to inspect after printing, SMT, reflow soldering, or wave soldering will have a significant difference in misjudgment rate.