What are the characteristics of non-destructive testing

Release time:2024-01-11Publisher:Jeenoce

Non destructive testing technology, also known as non-destructive testing, is an inspection method used to obtain physical and chemical information related to the quality of the test substance, such as content, properties, or components, without damaging its original state, chemical properties, etc.

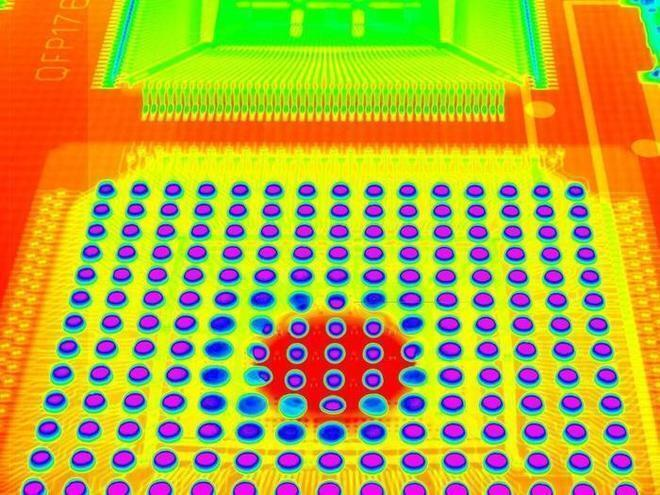

Non destructive testing, also known as non-destructive testing, refers to the use of changes in physical quantities such as heat, sound, light, electricity, and magnetism caused by internal structural abnormalities or defects in materials to detect internal and surface defects in various engineering materials, components, structural components, etc., without damaging the object being tested.

The biggest feature of non-destructive testing is that it can be carried out without damaging the material and structure of the specimen. So after implementing non-destructive testing, the inspection rate of the product can reach 100%.

However, not all items and indicators that need to be tested can undergo non-destructive testing, and non-destructive testing techniques also have their own limitations. Some tests can only use destructive testing, therefore, non-destructive testing cannot replace destructive testing at present. That is to say, for the evaluation of a workpiece, material, or machine equipment, it is necessary to compare and coordinate the results of non-destructive testing with those of destructive testing in order to make accurate evaluations.

In the past, the term non-destructive testing was originally referred to as non-destructive testing or non-destructive testing, and its different methods were also referred to as testing, such as radiographic testing, ultrasonic testing, magnetic particle testing, penetration testing, and so on. This term or writing is widely circulated and has been used to this day, with a usage rate no less than that of non-destructive testing.

With the rapid development of the manufacturing industry, the requirements for product quality inspection are becoming higher and higher. It is necessary to strictly inspect and accurately measure the internal structural dimensions of more and more critical and complex components and even internal defects of products.