The Testing Principles of X-ray Testing Equipment and X-ray Testing Machine

Release time:2024-01-05Publisher:Jeenoce

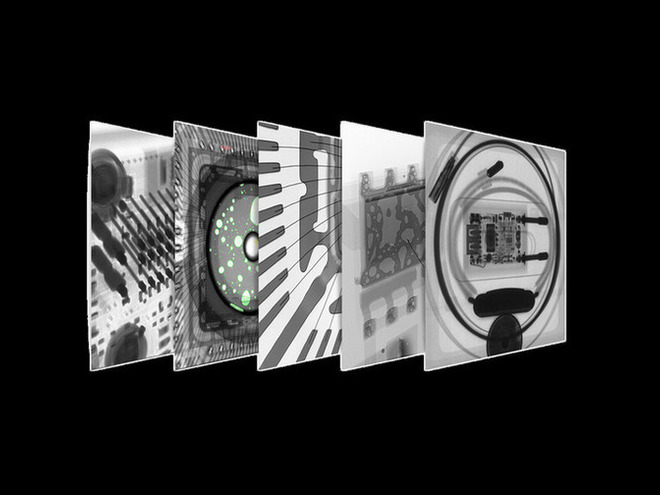

During the detection process, X-Ray passes through the sample to be tested and forms a three-dimensional image on the image. You can intuitively understand the two-dimensional and three-dimensional partial overall, perspective, or cross-sectional analysis of the product.

Then, through the analysis of X-ray images, the surface and internal quality of the inspected product are inspected under the premise of non-destructive testing of the product or the working condition of the raw materials. So as to identify the cause of product defects and solve the difficulties caused by production.

To understand X-ray testing equipment, we first need to understand what X-ray is? X-rays are rays that are invisible to the human eye but can penetrate objects. Has strong penetration ability, can accurately detect internal defects of the product, and find the root cause of defects. The penetrated product structure, through the imaging process, can be displayed on the screen or TV screen to obtain X-ray images with black and white contrast and hierarchical differences.

It can clearly, accurately, and intuitively display the internal structure, composition, material, and defect status of the tested object in the form of two-dimensional sectional images or three-dimensional stereoscopic images without damage to the detected object. It is known as the best non-destructive testing and assessment technology today.

X-ray testing is also an important method of conventional non-destructive testing, widely used in aviation, aerospace, nuclear power, national defense, medical and other industrial sectors. It has played an important role in industrial production and the national economy.

At present, in practical life, X-ray testing equipment has high imaging quality and can accurately provide reliable information on the true situation of defects in the tested parts.