回流焊机隔热系统的原理

Release time:2023-12-22Publisher:Jeenoce

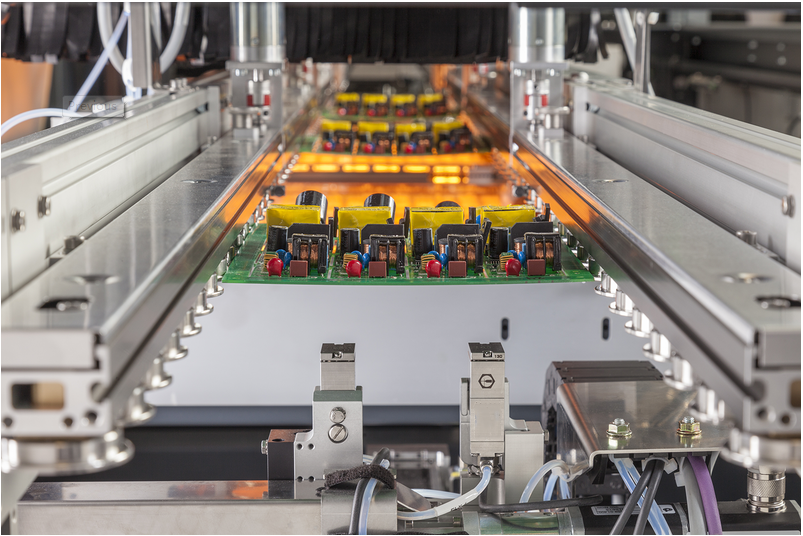

The principle of the reflow welding machine insulation system is to use insulation materials to conduct and diffuse heat, in order to reduce heat loss, improve thermal efficiency, and maintain temperature uniformity. Specifically, insulation systems generally consist of the following components:

1. Insulation materials: High temperature insulation materials such as ceramic fibers, glass fibers, or polyester fibers are usually used. These materials have good insulation performance and high temperature stability, which can effectively reduce heat loss and temperature uniformity.

2. Insulation board: Fixing insulation material on the shell or support structure of equipment to form an insulation board, used for insulation conduction and heat diffusion.

3. Fan or oil pump: In order to accelerate heat dissipation, it is usually necessary to equip a fan or oil pump in the insulation system to remove heat from the equipment.

4. Temperature controller: The temperature controller is used to monitor the internal temperature of the equipment and control the operation of the fan or oil pump according to the preset temperature range to ensure that the internal temperature of the equipment is stable within a range.

In general, the insulation system of the reflow welding machine uses insulation materials and insulation plates to isolate the conduction and diffusion of heat, and is equipped with auxiliary equipment such as fans or oil pumps and temperature controllers to ensure the thermal efficiency and temperature uniformity of the equipment.