New energy FPC/CCS/FFC/FDC automated dispensing production line

Release time:2023-12-15Publisher:Jeenoce

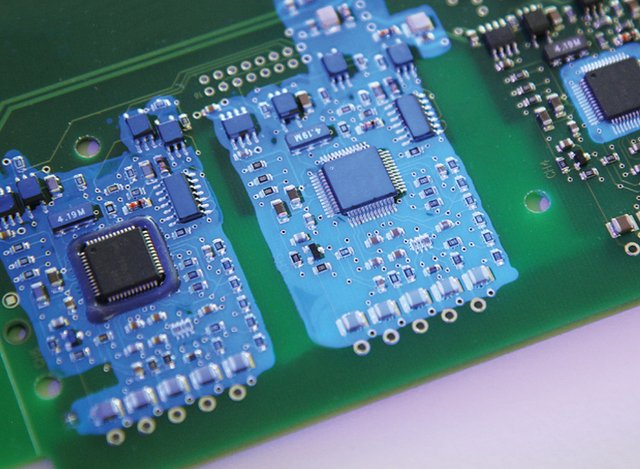

New energy FPC/CCS/FFC/FDC automated dispensing production line, suitable for dispensing 0.1-3m products; The production line equipment consists of a connector dispensing machine, a tin foil dispensing machine, an NTC dispensing machine, a lifting UV curing furnace, and a connecting platform. The main machine has four adhesive heads for dispensing operations simultaneously, resulting in a double increase in production capacity. The effective operating range for a single operation is 2m, and compared to traditional production lines, the space occupied is reduced by 30%.

Performance characteristics of new energy FPC/CCS/FFC/FDC automated dispensing production line equipment:

1. The dispensing part is designed with a quick release modular design, which is compatible with various adhesives such as UV glue and thermosetting glue;

2. Single and double valves can be freely selected; Dual valves can perform asynchronous position compensation operations, and can independently rotate from 0 to 360 °;

3. The device has strong compatibility, can be configured with a label scanner, has the function of docking with the MES system, and can achieve digital management;

4. UV LED curing can achieve real-time monitoring of single lamp bead damage and energy, and can monitor energy anomalies in real time, avoiding situations such as delamination and failure of the adhesive.

Application scope of new energy FPC/CCS/FFC/FDC automated dispensing production line

FPC/CSS dispensing for new energy vehicles, semiconductor packaging, PCB electronic component fixation and protection, SMT, NTC, nickel wafer industry dispensing and coating; LCD glass organic board packaging adhesion, mobile phone board coating or button gluing, speaker gluing, battery box gluing sealing, lighting product sealing, automotive parts coating, hardware parts coating and bonding, fabric anti slip coating, quantitative gas, liquid filling coating, chip bonding, etc.