How to perform preheating operation for reflow soldering?

Release time:2023-12-12Publisher:Jeenoce

The preheating operation of reflow soldering is a crucial step in the reflow soldering process, which helps to improve welding quality and reduce thermal damage. The following are the steps for performing reflow soldering preheating operation:

1. Determine preheating temperature and time: Before preheating, it is necessary to determine the appropriate preheating temperature and time. The preheating temperature and time are determined based on factors such as the material, thickness, and welding method of the welded components. Excessive preheating temperature can cause thermal damage to welded components, while low preheating temperature can affect welding quality.

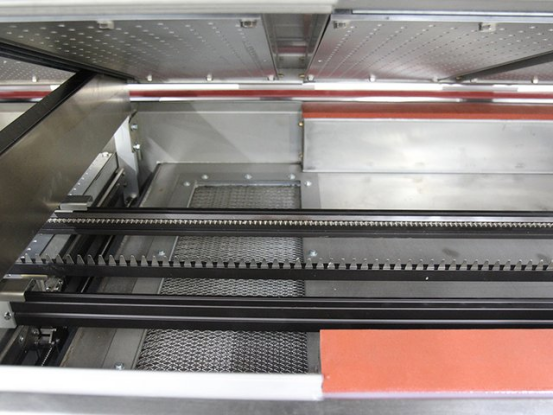

2. Choose the appropriate heating equipment: When performing preheating operations, it is necessary to choose the appropriate heating equipment. Common heating equipment includes heating lamps, heating plates, and heating gases. When selecting heating equipment, factors such as preheating temperature and heating time need to be considered.

3. Perform preheating operation: When performing preheating operation, it is necessary to place the welded components on the preheating equipment and adjust the settings of the heating equipment as needed. Preheating operations typically require multiple repetitions to ensure that the entire welded component is fully heated.

4. Record preheating data: When performing preheating operations, it is necessary to record preheating temperature, heating time, and other data. These data help to control welding quality in the subsequent welding process.

In summary, the preheating operation for reflow soldering requires attention to appropriate preheating temperature and time, selection of appropriate heating equipment, multiple preheating operations, and recording of preheating data. Preheating operation is an indispensable step in the reflow soldering process, which helps to improve welding quality and reduce the risk of thermal damage.