How to clean the coating machine equipment?

Release time:2023-12-12Publisher:Jeenoce

The booming development of other electronic industries such as circuit boards, phone cases, headphones, batteries, appliances, and light-emitting diodes has driven the rapid development of related industries, especially automation equipment. The coating machine is one of them. The demand for automatic coating machines in the optoelectronic industry is rapidly increasing. In addition to market demand, it is also closely related to support in the economic environment. Automatic coating machines have replaced slow and old-fashioned manual dispensing and coating. At present, coating machines have been widely used in fields such as circuit boards, mobile phone cases, headphones, batteries, appliances, and light-emitting diodes. Coating machines play a very important role in these industries. The stable and reliable operation and maintenance of the coating machine have become the focus of attention for equipment maintenance personnel, and the cleaning of the coating machine has also received attention from users. There are three main cleaning methods for coating machines:

1、 Traditional cleaning methods. Clean the mixing head with volatile solvents such as dichloromethane and DMF. This method is thorough and cost-effective, but the biggest problem is environmental pollution. Because it is a chemical, volatile, toxic, and non recyclable, it goes against the current trend of promoting green environmental protection. Therefore, its use is limited, gradually not accepted by the market, and gradually phased out.

2、 High pressure water cleaning. Although this method is non-toxic, low-cost, and easy to operate, there is a common problem of incomplete cleaning in the industry; Meanwhile, high-pressure water cleaning wastes water resources and generates a large amount of industrial wastewater, making it not the best cleaning method.

3、 Use recyclable and environmentally friendly solvents for cleaning. From a societal perspective, this method is the most popular, environmentally friendly, recyclable, and has good cleaning effects. But as an enterprise, due to high costs and the need for independent systems and equipment to be used together, it is often difficult for enterprises to accept. At present, there is no environmentally friendly and low-cost cleaning method in the coating machine market. Therefore, professional cleaning companies should increase their research and development efforts, actively innovate, and strive to develop cheap and environmentally friendly cleaning products as soon as possible to promote the development of the coating machine industry.

Specific cleaning methods for coating machine parts:

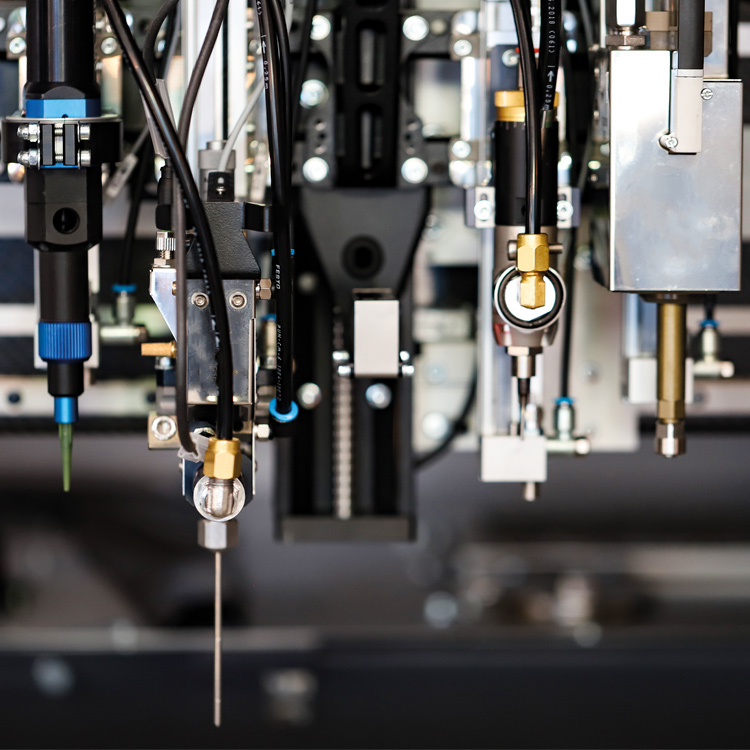

1. Glue dispensing needle: The bending or wear of the needle and stopper may have a significant impact on the quality of dispensing. If the temperature is high or not cleaned for a long time, the adhesive may also solidify or partially solidify on the inner surface of the needle, causing blockage. Regularly inspect the dispensing needle and promptly clean it if contamination is found. Soaking the needle in a compatible solvent is a common method, but the efficiency of only removing all uncured materials through soaking is too low. The glue can be blown out of the inner hole of the needle with a high-pressure spray of compatible solvent, and then the inner hole can be blown out with dry compressed air to dry the needle.

2. Metal template: In order to prevent detergent from corroding the adhesive of the template and screen, a pre washing process is used, using stronger detergent and manual operation to avoid contact between detergent and adhesive. Then, the template is cleaned with ordinary detergent.

3. Plastic templates: When cleaning plastic templates, electrostatic discharge may occur. Therefore, special anti-static cleaning agents should be used to avoid this phenomenon. At the same time, do not manually clean with a cloth, as plastic is prone to scratches and may lead to printing quality issues over the long term. The cleaning of the coating machine is an important task in the daily maintenance of the coating machine. Users attach great importance to it, but the cleaning method still needs improvement.