Process parameters that affect the quality of reflow soldering

Release time:2023-12-06Publisher:Jeenoce

The process parameters that affect the quality of reflow soldering mainly include the following points: 1. Temperature curve; 2. Reflow soldering preheating; 3. Reflow soldering insulation area; 4. The reflow zone of reflow soldering; 5. JEENOCE will explain in detail the cooling stages of reflow soldering.

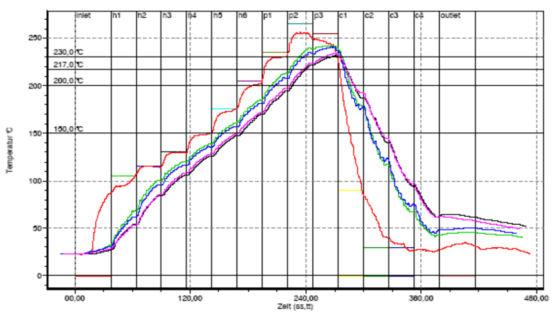

1. Establishment of reflow soldering temperature curve

The reflow soldering temperature curve refers to the curve of the temperature at a certain point on the SMA changing over time when it passes through the reflow furnace. The temperature curve provides an intuitive method to analyze the temperature changes of a component throughout the entire reflow soldering process. This is very useful for achieving optimal weldability, avoiding damage to components due to overheating, and ensuring welding quality. The temperature curve is tested using a furnace temperature tester, such as the SMT-C20 furnace temperature tester.

2. Reflow soldering preheating section

The purpose of this area is to heat up the PCB at room temperature as soon as possible to achieve the second specific goal, but the heating rate should be controlled within an appropriate range. If it is too fast, it may cause thermal shock and damage to the circuit board and components; If it is too slow, the solvent evaporation is not sufficient, which affects the welding quality. Due to the fast heating speed, there is a large temperature difference in the later stage of SMA in the temperature range. To prevent damage to components caused by thermal shock, the maximum speed is generally set at 4 ℃/s. However, the usual rate of increase is set at 1-3 ℃/s. The typical heating rate is 2 ℃/s.

3. Reflow soldering insulation section

The insulation section refers to the area where the temperature rises from 120 ℃ to 150 ℃ and the melting point of the solder paste rises. Its main purpose is to stabilize the temperature of various components within SMA and minimize temperature differences as much as possible. Give enough time in this area to catch up with the temperature of larger components and ensure that the flux in the solder paste is fully evaporated. At the end of the insulation section, oxides on the solder pads, solder balls, and component pins are removed, and the temperature of the entire circuit board reaches equilibrium. It should be noted that all components on the SMA should have the same temperature at the end of this section, otherwise entering the reflux section will result in various poor soldering phenomena due to uneven temperatures in each part.

4. Reflow soldering reflow section

The temperature of the heater is set high in this area, causing the temperature of the components to rapidly increase. The welding temperature in the reflow section varies depending on the type of solder paste used, and it is generally recommended to add 20-40 ℃ to the melting point temperature of the solder paste. For 63Sn/37Pb solder paste with a melting point of 183 ℃ and Sn62/Pb36/Ag2 solder paste with a melting point of 179 ℃, the temperature range is generally between 210-230 ℃, and the reflow time should not be too long to prevent adverse effects on SMA. The ideal temperature curve covers a small area beyond the melting point of the solder.

5. Reflow soldering cooling section

The lead-free tin powder in the solder paste in this section has melted and fully wetted the connected surface. Cooling should be carried out as quickly as possible, which will help to obtain bright solder joints with good appearance and low contact angle. Slow cooling can cause more decomposition of the circuit board into the tin, resulting in dull and rough solder joints. In the case of the end, it can cause poor soldering and weaken the bonding strength of the solder joint. The cooling rate of the cooling section is generally 3-10 ℃/s, and cooling at 75 ℃ is sufficient.

6. Reflow soldering bridging

During the heating process of reflow soldering, solder edge collapse can also occur. This situation occurs in both preheating and main heating scenarios. When the preheating temperature is within a range of several tens of degrees Celsius, the solvent used as a component of the solder will reduce its viscosity and flow out. If the trend of flow out is very strong, the solder particles will be squeezed out of the gold containing particles outside the welding area. If they cannot return to the welding area during melting, they will also form trapped solder balls. In addition to the above factors, factors such as whether the SMD component terminal is flat and good, whether the circuit board wiring design and solder joint spacing are standardized, the selection of solder mask coating method and its coating accuracy will all be the reasons for bridging.

7. Reflow soldering component monument

The warping of chip components under rapid heating is caused by the temperature difference between the two ends of the component caused by rapid heating. The solder on one side of the component is completely melted, resulting in good wetting, while the solder on the other side is not completely melted, causing poor wetting, which promotes the warping of the component. Therefore, heating should be considered from the perspective of time factors to form a balanced temperature distribution in the horizontal direction and avoid the generation of sudden heat. The main factors to prevent component warping include the following:

① Choose solder with strong adhesion, and the printing accuracy of the solder and the installation accuracy of the components also need to be improved;

② The external electricity of the component needs to have good wettability and wettability stability. Recommendation: Temperature below 40 ℃, humidity below 70% RH, the service life of incoming components should not exceed 6 months;

③ Adopting a small welding zone width size to reduce the surface tension generated by the melting of solder on the end of the component. Additionally, the printing thickness of the solder can be appropriately reduced, such as selecting 100 μ M;

④ The setting of welding temperature management conditions is also a factor in component warping. The usual goal is to heat evenly, especially before the welding rounded corners at the two connecting ends of the component are formed, and there should be no fluctuations in the balanced heating.

8. Poor wetting of reflow solder joints

Poor wetting refers to the external electricity of the solder and circuit substrate (copper foil) or SMD during the welding process, which, after being wetted, does not generate a reaction layer between them, resulting in solder leakage or insufficient soldering. Most of the reasons are due to contamination or adhesion of solder mask to the surface of the welding area, or the formation of a metal compound layer on the surface of the bonded material. For example, the presence of sulfides on the surface of silver and oxides on the surface of tin can lead to poor wetting. In addition, when the residual aluminum, zinc, cadmium, etc. in the solder exceeds 0.005%, the activation degree may be reduced due to the moisture absorption effect of the solder, which can also lead to poor wetting. Therefore, anti fouling measures should be taken on the surface of the welding substrate and the surface of the components. Select appropriate solder and set a reasonable welding temperature curve.