What is the difference between the preheating zone of wave soldering equipment and reflow soldering equipment

Release time:2023-12-05Publisher:Jeenoce

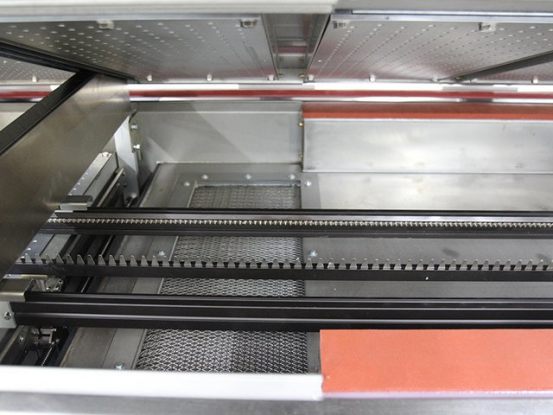

Both wave soldering equipment and reflow soldering equipment have preheating zones, so usually reflow soldering equipment can have many temperature zones, with an additional ten temperature zones. Wave soldering preheating zones are usually two to four. Why is this?

1、 Several Suitable Preheating Zones for Wave Welding Equipment

The number of preheating zones for wave soldering equipment in general enterprises should be determined based on actual demand and production scale. Generally speaking, the more preheating zones there are in wave soldering equipment, the better the welding quality and strength can be improved, but the corresponding equipment cost will also be higher. At the same time, the number of preheating zones also needs to consider factors such as the type of welding material, welding process parameters, and environmental temperature.

For general enterprises, wave soldering equipment is usually equipped with 2-4 preheating zones. This can meet most production needs and reduce equipment and production costs while ensuring welding quality and strength. If the production demand is high or the welding materials are complex, the number of preheating zones can be appropriately increased to ensure welding quality and strength.

The size of the preheating zone for wave soldering should be determined based on the welding material and welding process, rather than the larger the better. The function of the preheating zone is to heat the welding material to a certain temperature during the welding process to ensure welding quality and strength. If the preheating zone is too small, the welding material may not reach the required temperature, thereby affecting the quality and strength of the solder joint; If the preheating zone is too large, it will waste energy and time, and may also lead to excessive heating of the welding material, thereby affecting the performance and reliability of the solder joint.

Therefore, the size of the preheating zone should be determined based on the actual situation. Generally speaking, the thicker the welding material and the more complex the welding process, the larger the preheating zone required. When determining the size of the preheating zone, it is also necessary to consider factors such as the type of welding material, welding process parameters, and environmental temperature. The ultimate goal is to ensure welding quality and strength, improve production efficiency, and reduce production costs.

2、 How many suitable temperature zones are generally for reflow soldering?

The number of temperature zones for reflow soldering should be determined based on the welding material and welding process, rather than the more temperature zones, the better. The temperature range of reflow soldering usually includes preheating zone, heat wave zone, and cooling zone. The function of the preheating zone is to heat the circuit board and components to a certain temperature, in order to reduce welding stress and improve welding quality; The function of the heat wave zone is to heat the solder to the melting point, forming a solder joint; The function of the cooling zone is to rapidly cool and solidify the solder joints.

If there are too many temperature zones, it will increase equipment and maintenance costs, and may affect production efficiency. At the same time, the number of temperature zones also needs to consider factors such as the type of welding material, welding process parameters, and environmental temperature. Therefore, the number of temperature zones should be determined based on the actual situation. Generally speaking, the number of temperature zones in reflow soldering equipment is between 4-6, which is quite common. When determining the number of temperature zones, factors such as production efficiency, equipment cost, and maintenance cost need to be considered to ensure that reflow soldering equipment can meet production needs, improve production efficiency, and reduce production costs. For large, high-speed, and high-capacity enterprises, they can choose reflow soldering equipment in the 8-18 temperature range. Of course, the more temperature ranges there are, the higher the cost.

Whether it is reflow soldering equipment or wave soldering equipment, the more preheating and temperature zones there are, the better. The specific evaluation should be based on multiple aspects such as welding materials and welding processes, production capacity requirements, budget, etc.