Precautions for reflow soldering of LED circuit boards

Release time:2023-12-04Publisher:Jeenoce

The circuit board of LED beads must be reflow soldered at a proper temperature, otherwise it is easy to cause batch beads to die out and irreparable losses. So how can a circuit board with LED beads work without causing such unnecessary losses through reflow soldering. JEENOCE is here to explain to you.

1、 After adjusting the reflow soldering temperature curve of the circuit board with LED beads, it is necessary to perform various quality confirmations after passing through the first board before mass production can be carried out. This is the work of first piece confirmation in factory quality management.

2、 Before performing reflow soldering on circuit boards with LED beads, it is necessary to refer to the factory specifications of the LED beads and check their various technical parameters

1. Check the temperature resistance of LED bead packaging materials;

2. It depends on the material of the LED welding substrate, such as general PCB (fiberboard, etc.), aluminum substrate, ceramic board, etc;

3. It depends on the welding flux, whether it is high-temperature or low-temperature solder paste, or resin, etc;

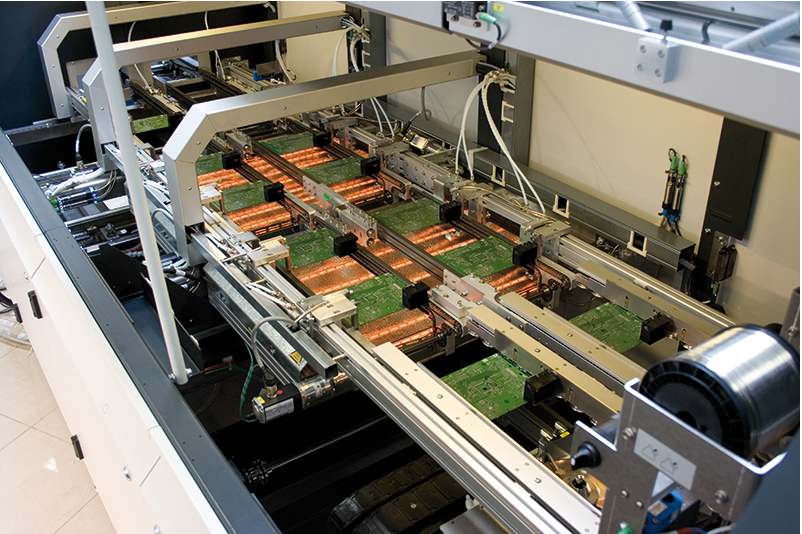

4. It should be determined based on the actual quality of LED reflow soldering equipment, including the number of temperature zones for LED reflow soldering, the control of parameters such as electrode flow rate, fan, and temperature settings for each zone.

3、 Reference for general adjustment parameters of circuit boards with LED beads that have undergone reflow soldering and LED beads

The minimum temperature is 150-170 degrees Celsius, and the best temperature is 240-245 degrees Celsius (the highest can be adjusted to 260 degrees Celsius, if 245 degrees Celsius can dissolve tin, do not adjust to 260 degrees Celsius). The time above 220 degrees Celsius cannot exceed 60 seconds, and if the temperature is increased, the time at 260 degrees Celsius cannot exceed 10 seconds. If it is a 7-temperature zone, the following settings can be referred to: 160, 170, 175, 180, 190, 210, 245, 220 If the LED beads are silicone lenses, BI58SN42 solder paste can be used, with a maximum temperature of 225 degrees Celsius. If it is a PC lens, first confirm the first piece of reflow soldering to ensure there are no problems before reflow soldering, but it is best not to use reflow soldering.