The application advantages of X-RAY detection equipment in semiconductor defect detection

Release time:2023-11-30Publisher:Jeenoce

The importance of semiconductors is self-evident in today's high-tech industry. However, with the continuous development of technology, the detection and quality control of semiconductors have become increasingly important. Among them, X-ray testing is a widely used technology in semiconductor testing.

Semiconductors are very fragile materials, and if their structure is damaged or contaminated, they may lose their original performance. Therefore, strict testing is required in the manufacturing process of semiconductors to ensure their quality and reliability. X-ray testing is a non-destructive testing method that can detect the internal structure and defects of semiconductors, thereby achieving comprehensive quality control.

The principle of X-ray detection of semiconductors is mainly to use X-rays to penetrate semiconductor materials and analyze their diffraction or scattering, in order to obtain information about the internal structure and defects of the materials. This detection method can not only detect micro defects inside semiconductors, but also detect their surfaces, thereby obtaining more comprehensive quality information.

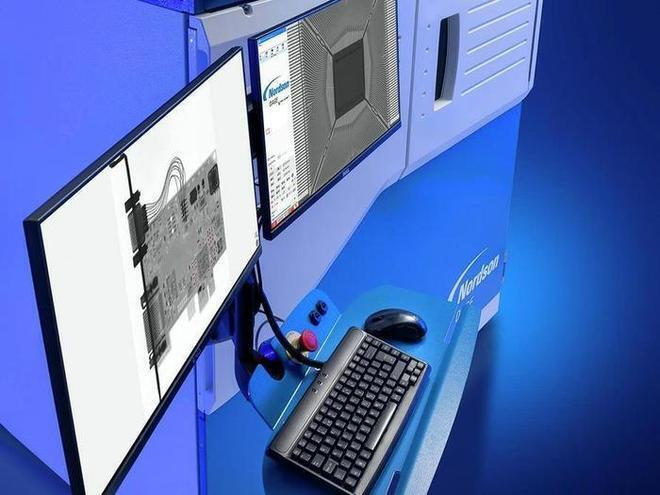

In the X-ray testing process, professional testing equipment and technical personnel are required. Among them, the most commonly used equipment is X-ray diffractometer and X-ray fluorescence spectrometer. Diffraction instruments are mainly used to analyze the crystal structure and defects of semiconductors, while fluorescence spectrometers can be used to analyze the elemental composition and chemical state of semiconductor surfaces. The professional level of these devices and technicians directly determines the accuracy and reliability of the testing.

In addition to non-destructive testing, X-ray testing also has another advantage, which is the ability to customize testing plans for different semiconductor materials. Different semiconductor materials have different crystal structures and chemical properties, therefore requiring different detection conditions and parameters. X-ray testing can be optimized and customized according to the characteristics of different materials, thereby achieving precise detection of different materials.

X-ray testing is a very important technology in the manufacturing and application of semiconductors. It can achieve non-destructive detection of the internal structure and defects of semiconductors, thereby improving the quality and reliability of semiconductors. With the continuous development and progress of technology, it is believed that X-ray testing technology will play an increasingly important role in the semiconductor industry.