The principle, method, and application scenario of X-ray detection of IGBT

Release time:2023-11-29Publisher:Jeenoce

JEENOCE will introduce you to the principles, methods, and application scenarios of X-ray detection IGBT, helping you understand the important position of this technology in the field of electronic manufacturing.

1、 The principle of X-ray detection of IGBT

X-ray is an electromagnetic wave with high energy and penetration ability, which can penetrate the surface of an object and generate phenomena such as scattering, reflection, and absorption. X-ray detection technology utilizes these characteristics of X-rays to detect and analyze the internal structure and defects of objects by measuring signals such as scattering, reflection, and absorption.

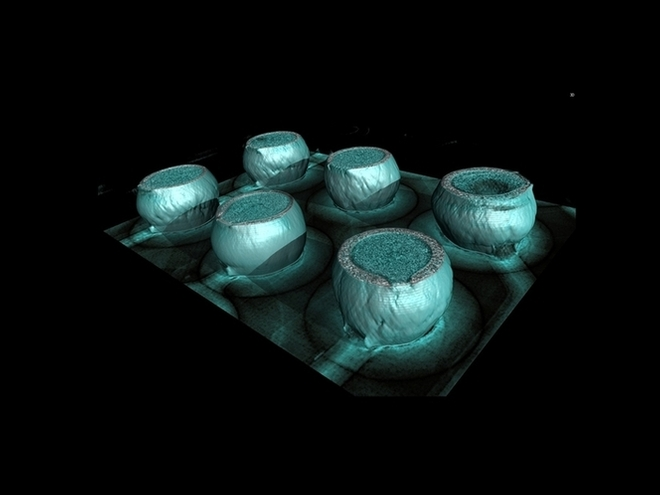

When X-ray testing IGBT, the X-ray source emits X-rays that are irradiated onto the IGBT chip. Different materials in the chip have different signals of scattering, reflection, and absorption of X-rays. By measuring these signals, the internal structure and defect information of the chip can be obtained. Meanwhile, X-ray detection technology can also analyze the metal film layer on the chip to evaluate its quality and reliability.

2、 Methods for X-ray detection of IGBT

The X-ray detection method for IGBT mainly includes the following steps:

1. Sample preparation: Select the IGBT chip to be tested as the sample and perform necessary treatments such as cleaning, drying, etc.

2. Data acquisition: Place the sample in the X-ray testing equipment, adjust the position and angle of the X-ray source and detector, and collect data.

3. Image processing: Process the collected data, such as filtering, enhancement, etc., to improve image quality.

4. Defect analysis: Perform defect analysis on the processed image to identify and evaluate the internal structure and defect information of the chip.

5. Result report: Based on the defect analysis results, write a testing report and provide an evaluation of chip quality and reliability.

3、 Application scenarios of X-ray detection of IGBT

X-ray inspection IGBT technology has a wide range of application scenarios in the field of electronic manufacturing, mainly including:

1. Quality control: In the IGBT production process, X-ray inspection technology is used to analyze the internal structure and metal film layer of the chip, which can effectively control product quality and timely detect and handle defects.

2. Failure analysis: When IGBT fails, X-ray detection technology can be used to analyze the cause of failure, such as structural defects inside the chip, peeling of metal film layers, etc., providing a basis for improving design and production processes.

3. Material research: X-ray detection technology can be used to study new materials and structures of IGBT materials, such as new high-temperature superconducting materials and nanomaterials, to promote the development of the electronic manufacturing field.

In summary, X-ray testing technology is playing an increasingly important role in the field of electronic manufacturing. By mastering the principles and methods of X-ray detection of IGBT, and applying this technology reasonably, the quality and reliability of IGBT can be effectively improved, production costs can be reduced, and strong support can be provided for the development of electronic manufacturing.