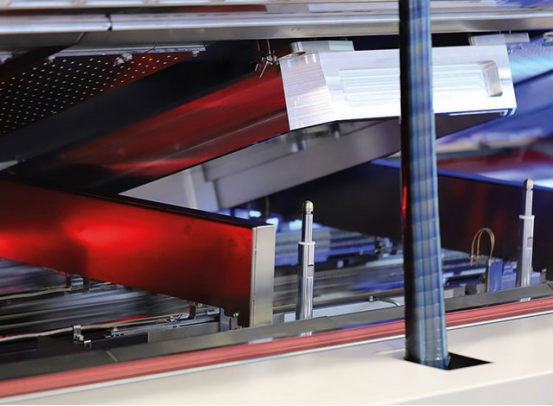

Introduction to heating methods of common reflow welding machines

Release time:2023-11-22Publisher:Jeenoce

Reflow welding machines can be divided into infrared, infrared hot air, hot air, vapor phase, hot plate, laser reflow welding machine, etc. based on the heating method used. Among them, reflow welding machines that belong to overall heating include vapor phase, infrared, infrared hot air, hot plate, hot air, etc.; reflow welding machines that belong to local heating include laser, focused infrared, beam machine, etc. At present, the three main types of reflow soldering that account for a large share in the market are JEENOCE. Let me share with you below.

1、 Infrared reflow soldering

Infrared reflow welding machines are divided into near-infrared reflow welding machines and far-infrared reflow welding machines. Due to the shielding effect, color sensitivity, uneven heating temperature, and no thermal convection when using near-infrared reflow welding, this type of equipment is no longer used. Far infrared reflow soldering has to some extent overcome the shielding effect during welding, effectively reducing color sensitivity, high heating efficiency, and energy saving. It was widely used as a leading product in the SMT field in the 1980s. The disadvantage is uneven heating, which can cause significant temperature differences between the center and edge positions of larger printed boards. At the same time, it is easily affected by the distribution of device positions and is not suitable for assembly and welding of printed boards with higher requirements.

2、 Forced convection hot air reflow soldering

Forced convection hot air reflow welding is a welding method that uses a convection jet nozzle or a heat-resistant fan to force the airflow to circulate, thereby achieving heating of the welded part. This type of device has emerged since the 1990s. Due to the use of this heating method, the temperature of printed boards and components is close to the gas temperature in the given heating temperature range, completely overcoming the temperature difference and shielding effect of infrared reflow soldering, so it is currently widely used. In forced convection hot air reflow welding equipment, the convective speed of the circulating gas is crucial. To ensure that the circulating gas acts on any area of the printed circuit board, the airflow must be fast enough. This can easily cause shaking of thin printed boards and displacement of components to a certain extent. In addition, using this heating method has lower efficiency and higher power consumption compared to heat exchange methods.

3、 Infrared hot air reflow soldering

This is a heating method that combines hot air convection and far-infrared heating. This method effectively combines the advantages of infrared reflow soldering and forced convection hot air reflow soldering, and is currently an ideal heating method. This type of equipment has been in use since the mid-1990s. Due to its full utilization of the strong penetration of infrared radiation, high thermal efficiency, and power saving, it effectively overcomes the temperature difference and shielding effects of infrared reflow soldering, and compensates for the impact of hot air reflow soldering on the gas flow rate caused by the requirement of too fast. Therefore, the market prospects are very broad.

The heating methods of JEENOCE reflow welding machines are convection hot air reflow welding and infrared hot air reflow welding. There are mainly six temperature zone reflow welding machines, eight temperature zone reflow welding machines, ten temperature zone reflow welding machines, and twelve temperature zone reflow welding machines to meet different customer needs.