What are the basic requirements for purchasing a curved PCB splitter?

Release time:2023-11-21Publisher:Jeenoce

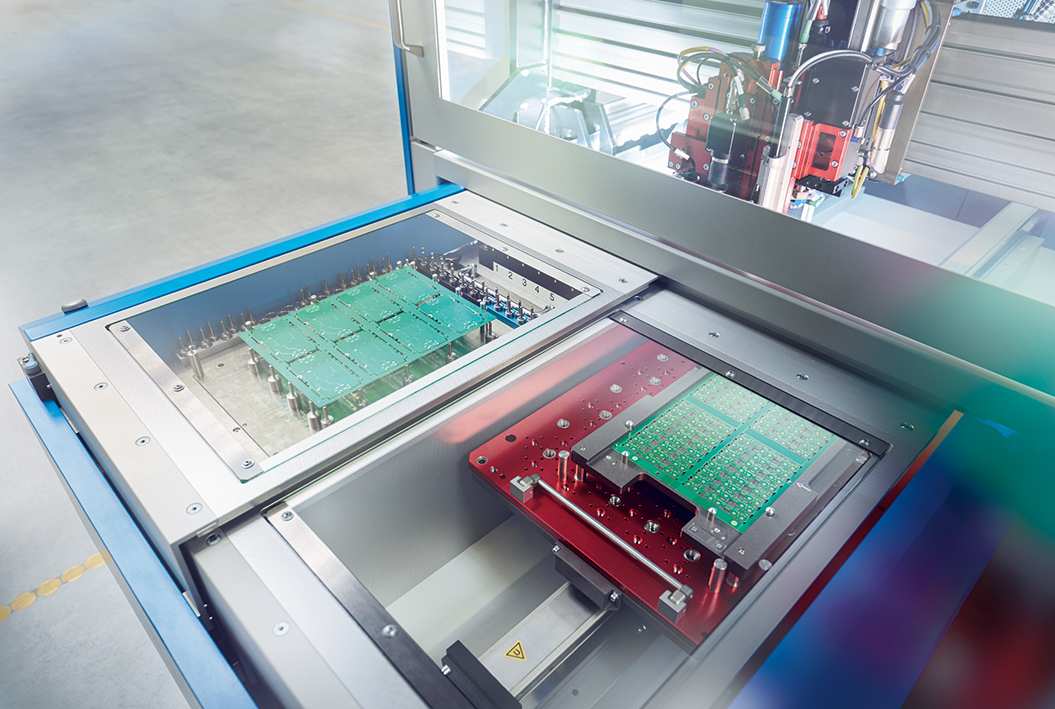

The specific requirements for curved PCB splitters may vary depending on different application fields and production needs. When selecting a curve dividing machine, it is necessary to select suitable equipment based on specific needs and budget, and ensure that it complies with relevant safety standards and regulations.

A curve dividing machine is a device used for cutting and separating sheets or combinations of sheets. The following are some common requirements for curve splitting machines:

1. Accuracy: The curve dividing machine needs to be able to accurately cut and separate sheets to meet design and accuracy requirements. It should be able to accurately control the cutting position, speed, and force, ensuring smooth cutting lines and high accuracy of straight lines or curves.

2. Automation: Modern curve dividing machines typically have automation functions, which can automatically complete the cutting and separation processes. It should have functions such as automatic feeding, automatic positioning, and automatic cutting to improve production efficiency and ease of operation.

3. Stability: The curve splitting machine needs to have a stable structure and operating state to ensure the stability and safety of the cutting and separation process. It should be able to withstand the forces and vibrations during the cutting process, while maintaining the stability of the machine and avoiding damage to operators and equipment.

4. Versatility: Curve splitting machines usually need to adapt to different sheet metal and cutting requirements. It should have versatility and be able to adapt to different shapes, sizes, and materials of plates to meet different production needs.

5. Safety: The curve splitting machine needs to have safety protection measures to prevent operators from getting injured during operation. This may include safety equipment such as safety shields, emergency stop buttons, safety sensors, as well as relevant safety operating procedures and training.