What process is reflow soldering?

Release time:2023-11-06Publisher:Jeenoce

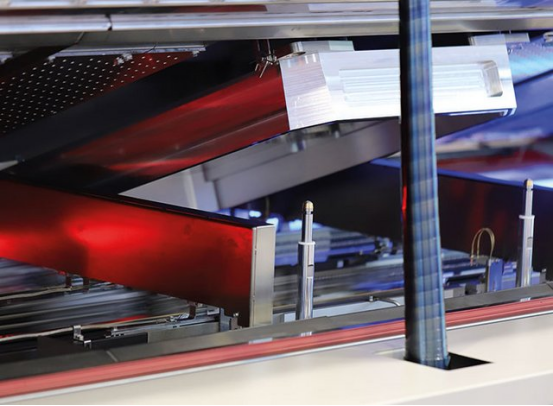

Reflow soldering, also known as surface mount technology (SMT), is a method of installing and connecting electronic components. In the reflow soldering process, electronic components are first fixed to the PCB (Printed Circuit Board) with adhesive, and then the entire assembly board enters the reflow furnace. In a reflow furnace, under high temperature conditions, the solder paste on electronic components is heated and melted, forming welding joints that weld the components and PCB together. Subsequently, in the cooling area, the solder joints solidify and the assembly board is welded.

Reflow soldering has the advantages of high efficiency, reliability, and space saving, and is widely used in the electronic equipment manufacturing industry. Reflow soldering technology has become one of the main assembly and connection processes in modern electronic manufacturing industry, especially in surface mount technology.

During the reflow soldering process, the following aspects need to be noted:

1. Temperature control: The temperature in the reflux furnace must be strictly controlled to ensure the quality and reliability of the solder joints. The melting point of different components varies, and it is necessary to choose a suitable reflux temperature curve based on the requirements of the welding material.

2. Solder paste selection: Select the appropriate solder paste according to different welding requirements. The composition and viscosity of solder paste can affect welding quality.

3. Adhesive: Use appropriate adhesive to bond the components to the PCB, and the adhesive must be able to maintain stability in high temperature environments.

4. Welding quality inspection: Conduct reliability testing and quality inspection on welding points to ensure that the welding quality meets the requirements.

In short, reflow soldering is a commonly used technology for connecting electronic components. By controlling temperature and selecting appropriate welding materials, efficient and reliable welding processes can be achieved, and it is widely used in the electronic manufacturing industry.