Requirements for temperature difference in reflow soldering furnace

Release time:2023-10-31Publisher:Jeenoce

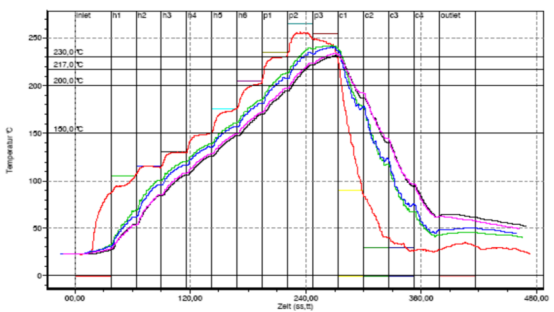

The requirements for temperature difference in reflow soldering furnaces vary depending on specific process requirements and the properties of welding materials. Generally speaking, during reflow soldering, it is necessary to control the temperature of the welding area to ensure welding quality. Therefore, when setting the temperature curve of the reflow soldering furnace, the following aspects need to be considered:

Preheating stage: The furnace temperature during the preheating stage should be appropriate to ensure welding quality. Generally speaking, the furnace temperature during the preheating stage should be slightly higher than the constant temperature stage in the welding area to ensure welding quality.

Constant temperature stage: The furnace temperature during the constant temperature stage should be kept stable to ensure welding quality. Generally speaking, the furnace temperature during the constant temperature stage should be slightly higher than that during the preheating stage to ensure welding quality.

Cooling stage: The furnace temperature during the cooling stage should gradually decrease to ensure welding quality. Generally speaking, the furnace temperature during the cooling stage should be slightly lower than that during the constant temperature stage to ensure welding quality.

It should be noted that when setting the temperature curve of the reflow soldering furnace, it is necessary to consider the requirements of the welding process and the actual situation, to ensure that the set curve has practical significance and can achieve the expected effect. At the same time, it is also necessary to regularly monitor and adjust the furnace temperature curve to ensure welding quality and production efficiency.