Analysis of the advantages of visual dispensing machines

Release time:2023-10-30Publisher:Jeenoce

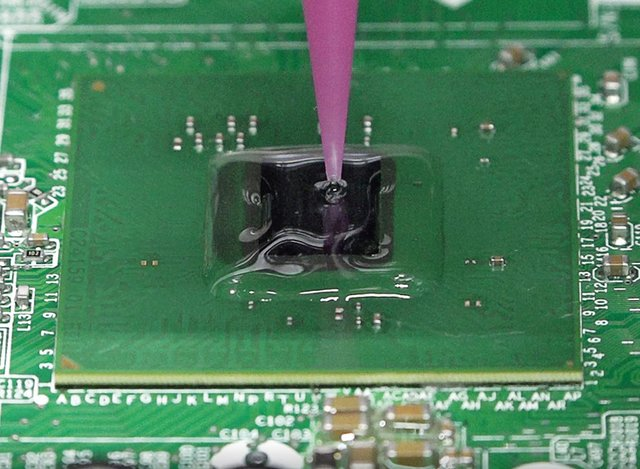

Compared to other ordinary dispensing machines, the key function of a visual dispensing machine is "vision", which simulates the position of products placed like human eyes and can automatically locate the product position for dispensing. It can be connected to a computer client for adjusting working parameters, such as the amount and time of glue output, which can be adjusted freely, making this type of glue dispenser more comprehensive in functionality and more applicable in the industry. If users need to perform higher demand and precision dispensing work, they can set an uninterrupted cycle dispensing mode in the visual dispensing machine to achieve the desired effect. In addition, the visual dispensing machine adopts a precise driving device to effectively enhance the dispensing accuracy and quality of the product, making the equipment work more stable and efficient.

In automated packaging production lines, the visual control system of the visual dispensing machine has replaced manual operation, not only improving productivity, but also greatly reducing defect rates. It can automatically complete the entire process of dispensing and conveying glue to the dispensing head according to the instructions issued by the system without manual intervention, which is clearly more advantageous compared to other dispensing equipment.

The characteristic of easy operation and learning of visual dispensing machines is very advantageous for frontline workers with low education. Because the simplicity of operation greatly improves their learning efficiency, enterprises do not need to spend more time and cost on employee on-the-job training, helping them save a lot of training costs. From a general perspective, visual dispensing machines enable enterprises to quickly achieve efficient product effects and subtly influence their reputation.

Advantages of the visual system:

0. No need for fixtures, correct the deviation between traditional dispensing manual labor and fixtures, and reduce defect rates

1. Fast recognition speed, capable of recognizing hundreds to thousands of objects per minute

2. High recognition accuracy, detection accuracy can reach micrometer level

3. Low environmental requirements, able to withstand high and low temperatures, with a wide range, not afraid of harsh environments and dangerous operations

4. Non fatigue, sustainable work

5. Not affected by subjective factors, stable and reliable detection quality

6. Low cost of continuous use, only requires initial investment in purchasing costs, and only needs to pay for electricity bills in the later stage