Characteristics and Use of Visual Splitter

Release time:2023-10-23Publisher:Jeenoce

1、 Functional features:

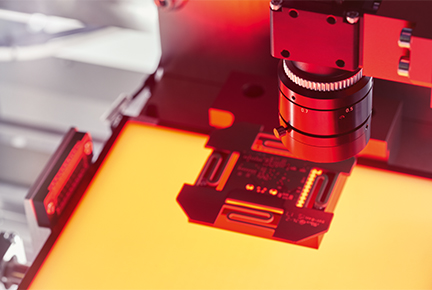

1. Equipped with a high pixel CCD magnifying lens, with auxiliary program teaching and editing functions, the accuracy is higher and more accurate, and the image is clearer. Convenient editing and modification of block programs and single step programs.

The loading and unloading device for PCBs that interact with two platforms can effectively reduce the idle time of the machine, thereby achieving ideal production efficiency.

3. Automatic MARK point positioning and correction system, with real-time display and simulated route tracking of the moving path, the display is clear at a glance, and the automatic alignment correction function has higher cutting accuracy. As long as the PCB is deviated within a certain range, machine vision can perform automatic route correction, relaxing the accuracy requirements for operators during board placement. Greatly improved work efficiency.

4. Tool life monitoring: After cutting a certain distance, the milling cutter will automatically rise and fall to another uncut blade position. The up and down distance and number of times can be set based on the blade length to extend the milling cutter life.

5. The transparent safety door design makes the processing process clear at a glance, and there is an emergency stop when opening the door to prevent accidents during processing, providing a safe inspection operating environment.

6. CCD alignment can simulate the path before slitting. Reduce unnecessary errors.

2、 Application:

1. The entire series is equipped with a high-speed CCD visual relative position element correction device, which is particularly suitable for high-precision and high production capacity PCB panel manufacturing industry.

2. Suitable for mobile phones, several cameras, GPS, PDA, and MODULE, as well as small multi board PCB sub boards.

3. Enlarged size is suitable for processing large circuit boards such as several televisions, PC hosts, workstations, servers, etc.

4. Standard governance tools or specialized preparation can be used to assist in improving production capacity through board cutting.

5. Utilize dual work platforms to place workpieces, reducing waiting time and increasing production capacity.