Advantages and Operation Methods of Milling Cutter Splitting Machine

Release time:2023-10-20Publisher:Jeenoce

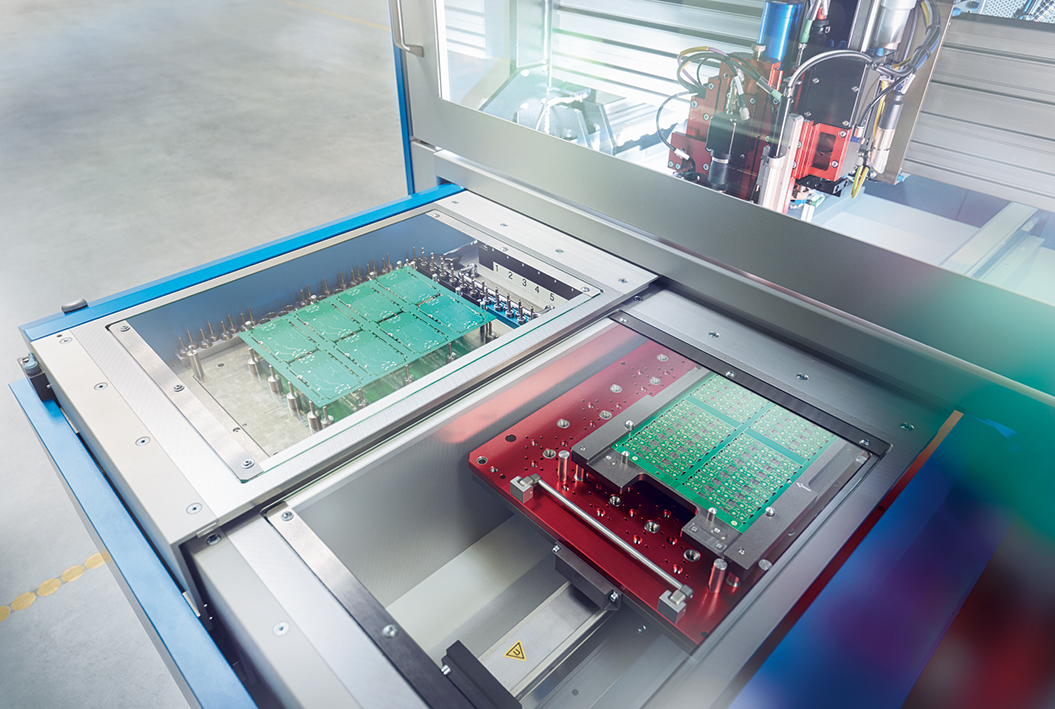

The milling cutter board splitting machine utilizes high-speed rotation of the milling cutter to cut multiple continuous PCB boards according to a pre programmed path, replacing manual breaking of PCB boards, improving product quality and reducing scrap rates. The milling cutter slitting machine adopts a linear motor system with fast slitting speed and high accuracy, and is equipped with offline programming function. Program editing can be manually taught or G-code imported, with import and export, board array copying, editing and modification functions, simplifying the program's straight time and accuracy.

1. According to the thickness of the sheet, the cutting speed can be selected.

2. The height of the upper knife can be adjusted according to the thickness of the board for better and precise cutting, with a cutting thickness of 0.5-3.2mm.

3. Equipped with a patented dust collection system to prevent dust residue on the surface of the PCB board. (Conforming to VDA19-1 standard)

4. Equipped with safety protection devices, the use process is safe and reliable to avoid danger caused by operational errors.

Operating Steps of Milling Cutter Splitting Machine

1. The operator of the fully automatic milling machine should determine the direction and front and back sides of the PCB board to be cut, and place it in a dedicated fixture. When placing it, gently press down with the palm of your hand. After confirming that it is in place, cover the cover of the splitting fixture tightly. At this time, everything is ready. The operator presses the green buttons on their left and right hands, and the workbench will automatically enter the dividing position. The spindle will start calibration and start working, and cutting simulation will be conducted. It is necessary to observe whether each position that needs to be cut is correct. When the simulation cutting is completed, the workbench will automatically exit.

2. After completing a series of inspections, the milling cutter and plate splitting machine will officially start processing. The operator needs to click the workbench button, and the plate splitting machine will start working. The vacuum cleaner, spindle, electrostatic eliminator, etc. will also automatically start. When working on the dividing machine, it is important to observe whether the cutting position is correct. If the cutting position is incorrect, offset, or not in the cutting position, there are red stop buttons on the left and right sides of the machine. At this time, as long as one person is pressed, the machine will immediately stop. After the machine stops, an engineer needs to be found to solve the problem.

3. After the milling cutter slitting machine completes the cutting of the PCB board, the workbench will automatically exit, and the cut PCB boards are all qualified. If there are any unqualified products, it is necessary to find an engineer to modify the milling cutter operation path. After confirming that the cut PCB boards are qualified, the operator can take out the processed PCB boards and reinsert them into the fixture.